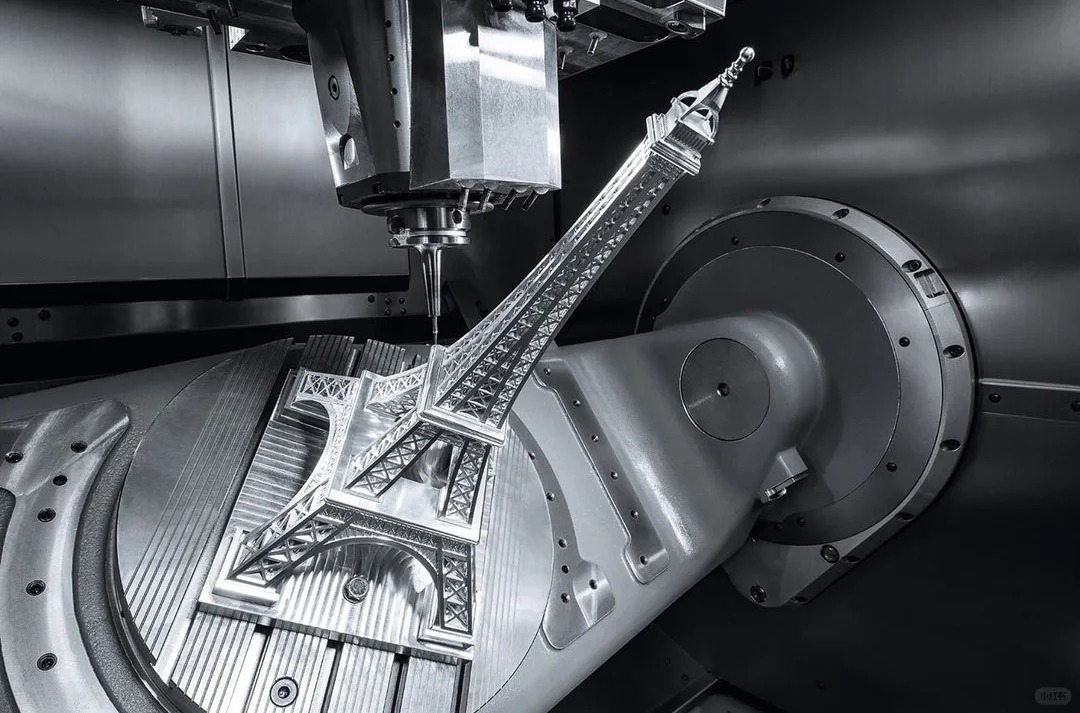

At first glance, the component in the video above might look like a simple piece of plumbing—a bent pipe designed to connect two points. In many applications, an off-the-shelf fitting would suffice. But in the demanding worlds of medical technology, food processing, aerospace, and high-performance hydraulics, the difference between a standard fitting and a precision-machined component is the difference between reliability and failure, between safety and risk.

A standard fitting can move fluid. A precision-machined stainless steel elbow, like the one showcased, is engineered to control it with absolute certainty. This control isn’t an accident; it’s the direct result of a manufacturing philosophy where every angle, every surface, and every internal passage is meticulously planned and executed.

For engineers and product designers working on critical systems, settling for “good enough” is not an option. Let’s delve into what elevates a piece of metal from a simple connector to a mission-critical component and explore why custom CNC machining is the only way to achieve this level of performance.

1. Custom Fluid Path Design: When 90 Degrees Isn’t Enough

One of the most significant limitations of standard, off-the-shelf fittings is their lack of versatility. You are constrained to standard angles (like 45° and 90°), standard lengths, and standard connection types. This often forces designers to compromise, creating convoluted fluid paths with extra connectors, adapters, and hoses. Each additional connection is a potential leak point, an additional source of turbulence, and another component to procure and inventory.

The CNC Machining Advantage:

Precision CNC machining liberates design from these constraints. Using advanced 5-axis CNC technology, we can manufacture fluid components with geometries that are perfectly tailored to their application.

- Non-Standard Angles & Complex Geometries: Need a 73-degree elbow to navigate around a critical sensor? Or a fitting that combines a bend, a T-junction, and a mounting flange into a single, monolithic part? CNC machining makes this possible. This ability to create complex, integrated components drastically simplifies assemblies, making them more compact, lightweight, and reliable.

- Optimized Flow Dynamics: We can machine elbows with a true, continuous radius on the internal bend, minimizing pressure drop and turbulence. For sensitive fluids or high-velocity systems, this smooth, uninterrupted flow is essential for maintaining efficiency and preventing unwanted effects like cavitation.

- Reduced Leak Points: By integrating multiple features into a single machined part, we eliminate the need for threaded joints, welds, and extra seals. In a high-pressure hydraulic system or a sterile medical device, reducing the number of potential failure points is paramount for safety and long-term performance.

This design freedom means your fluid system can be built for optimal performance, not just to accommodate the limitations of standard parts.

2. The Science of Smooth: Superior Surface Finish (Low Ra)

The mirror-like polish on the stainless steel elbow is more than just aesthetically pleasing—it’s a critical functional feature. Surface finish, technically measured as Roughness Average (Ra), quantifies the microscopic peaks and valleys on a material’s surface. A lower Ra value signifies a smoother, more uniform surface. While a standard cast or forged fitting might have a rough, textured surface, a precision-machined component can achieve a near-flawless, low Ra finish.

Why Surface Finish is Mission-Critical:

- Sanitation and Sterilization (Food & Medical): In food processing and medical device applications, hygiene is non-negotiable. A rough surface contains microscopic crevices where residue can accumulate and bacteria can colonize. A smooth, polished surface is far easier to clean, sterilize (e.g., via Clean-in-Place systems), and keep free of contaminants. This is why sanitary fittings are defined by their low Ra surface finish.

- Corrosion Resistance: Stainless steel is prized for its corrosion resistance, but this property can be enhanced or compromised by its surface finish. A smoother surface has less exposed surface area and fewer initiation sites for corrosion or pitting, especially in harsh chemical environments.

- Reduced Friction and Wear: In high-performance systems, a smooth surface reduces fluid friction, leading to lower energy consumption and less heat generation. It also reduces wear on any mating parts, such as seals or O-rings, extending the operational life of the entire assembly.

Achieving this level of finish requires a multi-stage process of controlled machining, followed by expert polishing and electropolishing techniques, all while maintaining the part’s critical dimensional tolerances.

3. Unseen Perfection: The Flawless Internal Bore

Perhaps the most important feature of a precision fluid fitting is the one you can’t easily see: the quality of the internal bore. The path the fluid travels must be perfect. Standard manufacturing methods, like casting or drilling, can leave behind tiny, sharp fragments of metal called burrs.

The Dangers of Internal Burrs:

Burrs are the silent killers of high-performance systems.

- System Contamination: A burr can dislodge during operation and travel downstream. In a hydraulic system, it can clog a valve or score a piston cylinder, causing catastrophic failure. In a medical fluid line, it represents a dangerous foreign-body contaminant.

- Turbulence and Flow Disruption: Even small burrs can disrupt the laminar flow of a fluid, creating turbulence that reduces efficiency and can damage sensitive fluids.

- Seal Damage: When a fitting is installed, burrs at the edge of the bore can slice or shred O-rings and other seals, creating immediate and hard-to-diagnose leaks.

The Precision Machining Guarantee:

We treat the internal bore with the same precision as the external surfaces. Our process includes:

- Optimized Tooling and Machining Strategies: We use specialized tooling and cutting parameters to minimize burr formation from the outset.

- Meticulous Deburring Processes: After machining, every part undergoes a rigorous deburring process. This can range from manual deburring under magnification by skilled technicians to advanced methods like thermal or electrochemical deburring for complex internal passages.

- Borescope Inspection: We use high-resolution borescopes to visually inspect the internal pathways of our components, guaranteeing they are completely free of burrs and surface imperfections.

This commitment to a flawless internal bore ensures cleaner, safer, and contamination-free performance for the life of your product.

Conclusion: Invest in Certainty

The custom stainless steel elbow is a perfect example of how precision CNC machining delivers value far beyond the component itself. It’s an investment in the overall performance, safety, and reliability of your entire system.

By partnering with an expert CNC machining service, you gain:

- Design Freedom: Build the most efficient system possible, not one compromised by off-the-shelf parts.

- Material Integrity: Full traceability of materials like 316L stainless steel, with certifications to meet industry standards.

- Functional Excellence: Guaranteed performance through superior surface finishes and flawless internal bores.

When your application demands uncompromising control over fluid dynamics, don’t settle for a standard fitting. Demand a precision-engineered solution.

Is your project facing challenges that an off-the-shelf component can’t solve? Contact our engineering team today for a consultation. We specialize in turning complex fluid handling challenges into reliable, high-performance realities.