When engineers think about manufacturing plastic parts, their minds often jump directly to injection molding. For decades, it has been the go-to method for producing plastic components, and for good reason—in high volumes, it’s incredibly efficient and cost-effective.

But what about when “high volume” isn’t the primary goal? What if the top priorities are speed, iteration, extreme precision, and complex geometry?

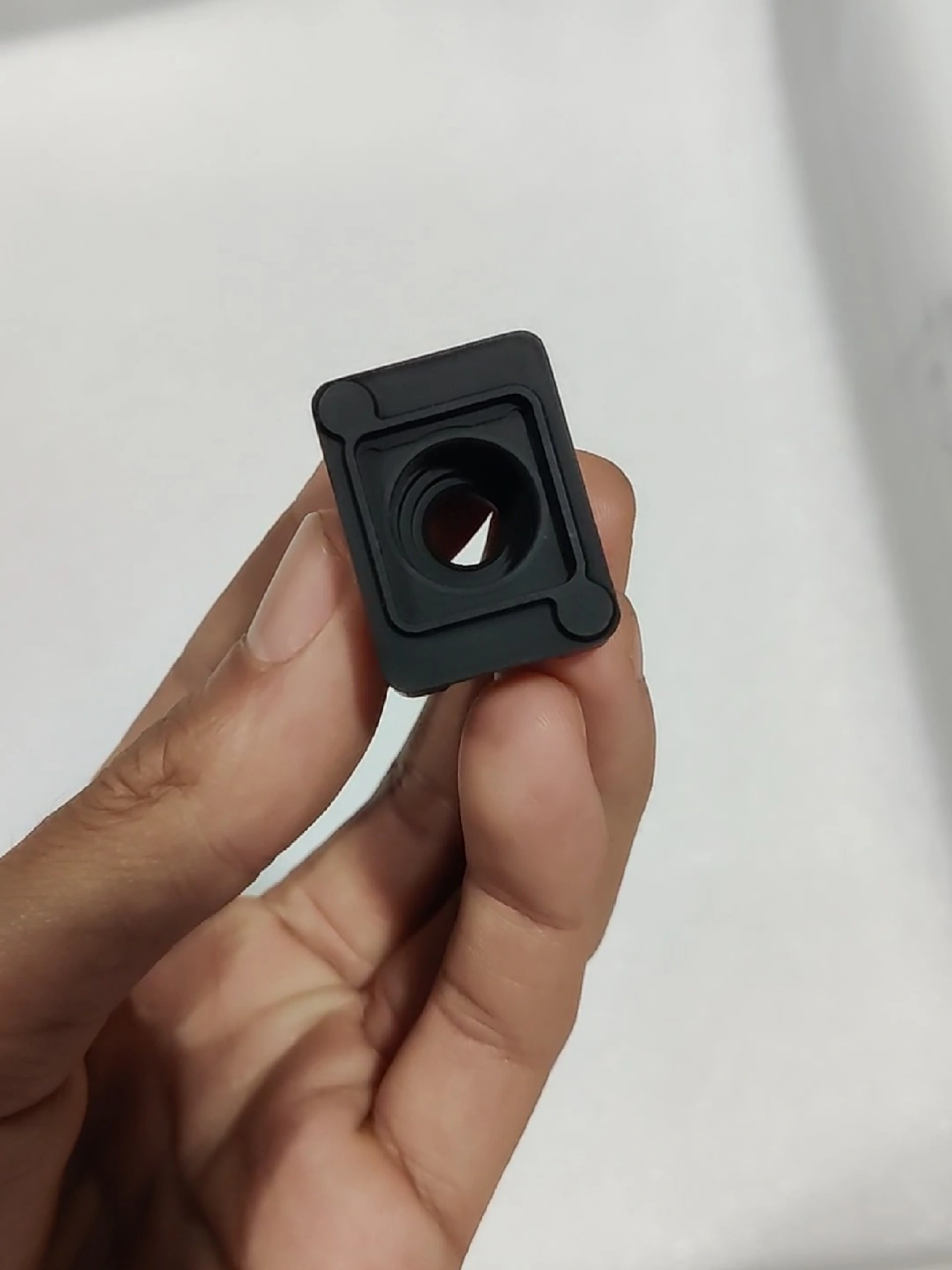

This is where another manufacturing paradigm shines. As the video above demonstrates with a small, intricate POM (Delrin) component, not all plastic parts are born from a mold. For a significant and growing number of applications, CNC machining—a subtractive process that carves parts from a solid block of material—is not just an alternative, but the superior choice.

For engineers, product developers, and innovators, understanding the strategic advantages of machined plastics is key to faster development cycles, better-performing products, and true design freedom. Let’s explore why CNC machining is often the smarter choice for your critical plastic components, from initial prototypes to low-volume production runs.

The Injection Molding Reality: A Tool for Mass Production

First, it’s important to give injection molding its due. It is an engineering marvel responsible for billions of parts that shape our modern world. The process involves injecting molten plastic into a precision-made steel mold (or “tool”) under high pressure. Once cooled, the part is ejected, and the cycle repeats, capable of churning out thousands of identical parts per day.

However, this efficiency comes with significant trade-offs, especially in the early stages of product development:

- High Upfront Tooling Costs: The steel mold is a complex, expensive piece of equipment. Costs can range from thousands to tens of thousands of dollars, or even more, representing a major capital investment before a single part is produced.

- Long Lead Times: Creating that mold is a lengthy process, often taking weeks or even months.

- Design Constraints: The molding process has inherent geometric limitations. Sharp internal corners are impossible, draft angles are required for part ejection, and inconsistent wall thicknesses can lead to defects like sink marks and warpage.

- Lack of Flexibility: Once the mold is made, design changes are difficult and expensive. A small tweak could require a complete re-tooling.

These factors make injection molding a poor fit for prototyping, low-volume manufacturing, or parts that demand a level of precision that the molding process simply cannot guarantee.

The CNC Machining Advantage: Speed, Precision, and Flexibility

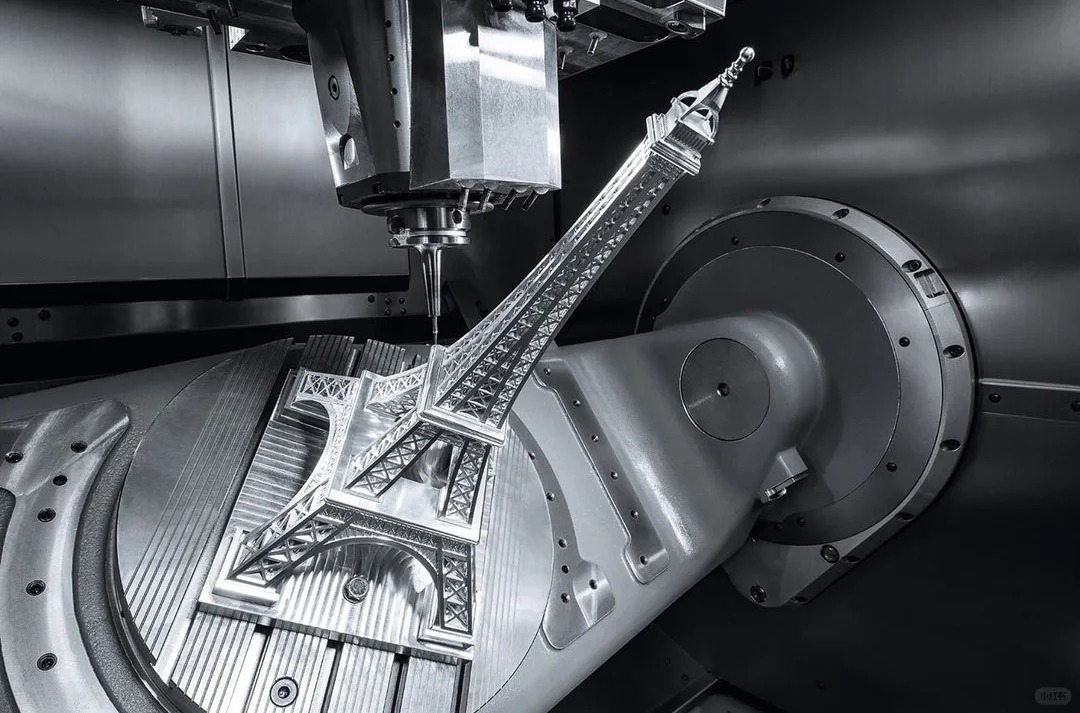

CNC machining for plastics flips the script. Instead of adding molten material to a cavity, it starts with a solid block of engineering-grade plastic and precisely removes material with high-speed cutting tools, guided by a digital CAD file. This fundamental difference unlocks four key advantages.

1. Unparalleled Speed for Prototyping and Production

The most immediate benefit of machining is the elimination of tooling. There is no mold to create.

- From CAD to Part in Days: The process is direct. Your 3D CAD model is converted into a CAM program, the plastic stock is loaded into the machine, and cutting begins. This means you can have a functional, end-use prototype in your hands in a matter of days, not weeks.

- Accelerated Iteration: This speed is a game-changer for product development. You can test a design, identify a flaw, make a change to the CAD file, and have a revised part machined almost immediately. This “fail fast, learn faster” approach drastically shortens the development cycle and leads to a better final product.

2. Superior Precision and Geometric Freedom

While injection molding tolerances are typically measured in tenths of a millimeter, CNC machining operates on a different level.

- Tight Tolerances: We can hold tolerances on machined plastic parts down to a few microns (a fraction of the width of a human hair). This is essential for components in medical devices, optical assemblies, and complex electromechanical systems where a precise fit is non-negotiable.

- Sharp Corners and Complex Features: The part in the video showcases features that are difficult or impossible to mold. CNC machining can create sharp internal corners, deep pockets with straight walls, undercuts, and precise threads without the need for draft angles or complex mold actions. This gives designers the freedom to create parts optimized for function, not limited by the manufacturing process.

3. Absolute Material Integrity and Consistency

A machined part is fundamentally different from a molded one at the material level.

- Machined from Solid Stock: By carving from a solid, homogenous block of polymer, the final component is free from the internal stresses, voids, and weld lines that can occur in injection molding. Weld lines—where two fronts of molten plastic meet in a mold—are notorious weak points. A machined part has none.

- True Material Properties: The finished part retains the full, predictable mechanical properties of the raw material stock. This is critical for parts that will undergo mechanical stress, as their performance in real-world use will match the engineering specifications and FEA simulations. There are no hidden defects to cause unexpected failures.

4. Cost-Effectiveness for Low-Volume Manufacturing

Without the massive upfront cost of a mold, CNC machining is the clear economic winner for lower quantities.

- No Tooling Amortization: For production runs from a single prototype up to several thousand units, the per-part cost of machining is often significantly lower than molding because you are not trying to amortize a $10,000 mold over a small number of parts.

- On-Demand Production: This opens the door for on-demand manufacturing, allowing you to produce parts as needed without holding large amounts of inventory.

Spotlight on POM (Delrin): A Perfect Match for Machining

The material featured in the video, POM (also known by the trade name Delrin®), is a perfect example of an engineering thermoplastic that excels when machined. It is prized for its high stiffness, dimensional stability, low friction, and excellent wear resistance. Its machinability is superb, allowing it to be cut cleanly to produce a smooth surface finish and hold very tight tolerances, making it a top choice for gears, bushings, jigs, fixtures, and precision mechanical components.

Your Decision Checklist: CNC Machining vs. Injection Molding

So, how do you decide which process is right for your project?

Choose CNC Machining for your plastic parts if:

- You need parts FAST for prototyping or quick-turn production.

- Your required quantity is low (typically from 1 to a few thousand).

- Your design requires extremely tight tolerances that molding cannot achieve.

- Your part has complex features like sharp internal corners, undercuts, or threads.

- Maximum material strength and integrity are critical, and you cannot risk voids or weld lines.

- You anticipate making design changes during the development process.

Conclusion: The Right Process for the Right Job

CNC machining isn’t a replacement for injection molding; it’s a powerful and strategic tool in the modern engineer’s toolkit. By understanding its unique advantages, you can break free from traditional manufacturing constraints, innovate faster, and create higher-performing products.

For your next plastic component project, look beyond the mold. Consider the speed, precision, and freedom that CNC machining offers.

Exploring the best manufacturing option for your next plastic component? Contact our team today. We specialize in precision machining of engineering plastics and can help you determine the most effective path from design to a finished part.