In manufacturing, there’s a common rule of thumb: for low quantities, you CNC machine; for high quantities, you injection mold. But what happens when your project falls into that ambiguous middle ground? What is the right process for 500, 1,000, or even 1,500 plastic parts?

For many, a quantity like 1,500 immediately brings injection molding to mind. The economics of scale seem to point in that direction. However, as our recent production run of 1,500 precision resin assemblies demonstrates, choosing the right manufacturing process is a strategic decision that goes far beyond a simple volume calculation.

The conventional wisdom about a “crossover point” where molding becomes cheaper is an oversimplification. A truly optimal manufacturing strategy considers not just the per-part cost, but the total cost of time, risk, and precision.

In this case study, we’ll break down the strategic factors that made CNC machining the clear and definitive winner for this 1,500-unit project, and provide a framework to help you make the right choice for your own.

Factor #1: Speed-to-Market Dominance

In today’s competitive landscape, timing is everything. Being the first to market, meeting a critical project deadline, or responding quickly to customer demand can be the difference between success and failure. This is where CNC machining offers an almost unbeatable advantage.

The Injection Molding Timeline:

- Design Finalization: The part design must be 100% locked in.

- Mold Design (DFM): The part is reviewed for manufacturability, and a complex steel mold is designed. This requires adding draft angles, planning for ejector pins, and optimizing gates.

- Mold Fabrication: The mold itself is machined from hardened steel—a meticulous and time-consuming process. (Typical time: 4-12 weeks)

- Mold Testing (T1 Samples): The first parts are molded and inspected. Adjustments and “tuning” of the mold are almost always necessary.

- Production Run: Once the mold is approved, mass production can begin.

The CNC Machining Timeline:

- Design Finalization: The part design is confirmed.

- CAM Programming: The CAD file is used to generate toolpaths for the CNC machine. (Typical time: 1-2 days)

- Production Run: Machining begins immediately. Parts can start coming off the machine within days of receiving the final design.

For this project, the most significant factor was the client’s urgent need to get their product to market. By choosing CNC machining, we completely bypassed the multi-month delay associated with mold fabrication and testing. We moved directly from CAD to production, delivering 1,500 finished, high-quality assemblies in a fraction of the time. When market timing is critical, this speed is not just a convenience; it’s a powerful competitive weapon.

Factor #2: No Tooling Investment and Reduced Financial Risk

The single largest barrier to entry for injection molding is the upfront cost of the mold, often referred to as “tooling.” A high-quality steel mold for a part of moderate complexity can easily cost anywhere from $5,000 to $50,000+.

This represents a substantial capital investment and a significant financial risk:

- Sunk Costs: If the product doesn’t succeed in the market or if the design needs to be updated, that entire tooling investment is lost.

- Design Inflexibility: Making a change to a steel mold is difficult, expensive, and sometimes impossible. Even a small design tweak can necessitate costly modifications or a completely new mold, adding more weeks and thousands of dollars to the project.

By opting for CNC machining, this project completely eliminated the tooling investment. This provided immense financial flexibility and de-risked the entire venture. If a design modification had been required mid-way through the run, it would have been a simple matter of updating the CAD file and the CAM program. This agility is invaluable, especially for new products where market feedback might necessitate future design iterations. The capital that would have been tied up in a static piece of steel was instead available for other critical business needs.

Factor #3: Uncompromised Precision, Complexity, and Quality

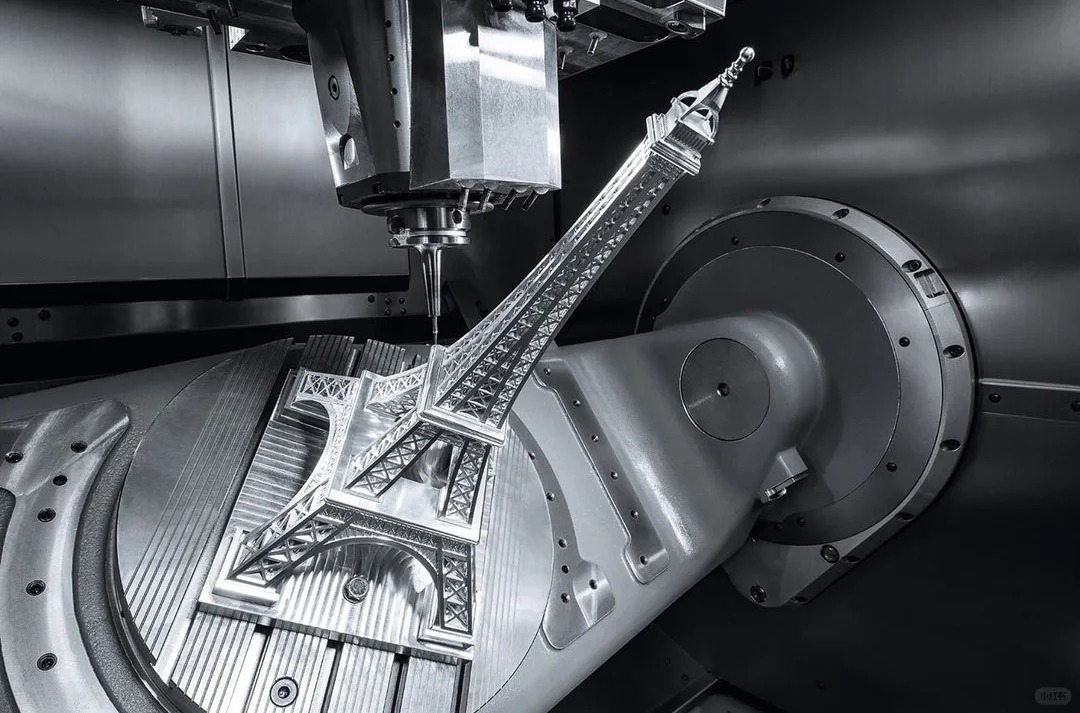

The components in the video are not simple shapes; they are intricate parts of a larger assembly. This means that fit, function, and dimensional accuracy are paramount.

CNC Machining Guarantees:

- Tight Tolerances: CNC machining routinely achieves tolerances far tighter than what is practical or cost-effective with injection molding. For this assembly, where multiple parts had to mate perfectly 1,500 times, the precision of CNC was non-negotiable.

- Superior Material Integrity: A machined part is carved from a solid, homogenous block of resin. This means it is free from the potential defects inherent to injection molding, such as:

- Weld Lines: Weak points where two fronts of molten plastic meet.

- Sink Marks: Divots caused by uneven cooling in thick sections.

- Voids: Internal air bubbles.

- Warpage: Distortion due to internal stresses from the molding process.

- Geometric Freedom: CNC machining excels at creating sharp corners, deep pockets, and complex internal features without the need for the draft angles required to eject a part from a mold. This ensures that every single one of the 1,500 units meets the exact design specifications without compromise.

For a high-performance assembly, guaranteeing that every component is dimensionally perfect and structurally sound is the only way to ensure reliable product performance and avoid costly recalls or failures in the field.

Beyond Prototyping: CNC Machining for Bridge and Low-Volume Production

This project perfectly illustrates that CNC machining is far more than just a prototyping tool. It serves two critical roles in modern manufacturing:

- Bridge Production: It acts as a “bridge” to get a product to market immediately while high-volume injection mold tooling is being prepared in the background. This allows a company to start generating revenue and gathering market data months earlier.

- Low-Volume Manufacturing: For many products with life cycles of a few hundred to a few thousand units, CNC machining is the most logical and cost-effective production method for the entire product run.

Making the Right Call for Your Project

Navigating the crossover point between machining and molding requires a holistic view. Ask yourself these key questions:

- How critical is speed-to-market? Can you afford to wait 2-3 months for tooling?

- How stable is your design? Is there any chance you will need to make changes after launch?

- What is your appetite for financial risk? Are you prepared to make a significant upfront investment in tooling?

- What level of precision do your parts require? Do they need to hold tight tolerances for assembly or performance?

For this 1,500-part run, the answers were clear. The need for speed, risk aversion, and high precision made CNC machining the indisputably optimal path.

Navigating the crossover point between manufacturing processes for your own project? Let’s discuss your specific requirements. We can help you analyze the trade-offs and determine the most efficient and cost-effective production path to success. 🤝