Who says structural components can’t be beautiful? In the world of high-performance engineering, there’s often a false dichotomy between form and function. A part is either strong and heavy, or it’s lightweight and delicate. It’s either built for pure utility, or it’s designed for aesthetics.

But what if a single component could be all of these things at once?

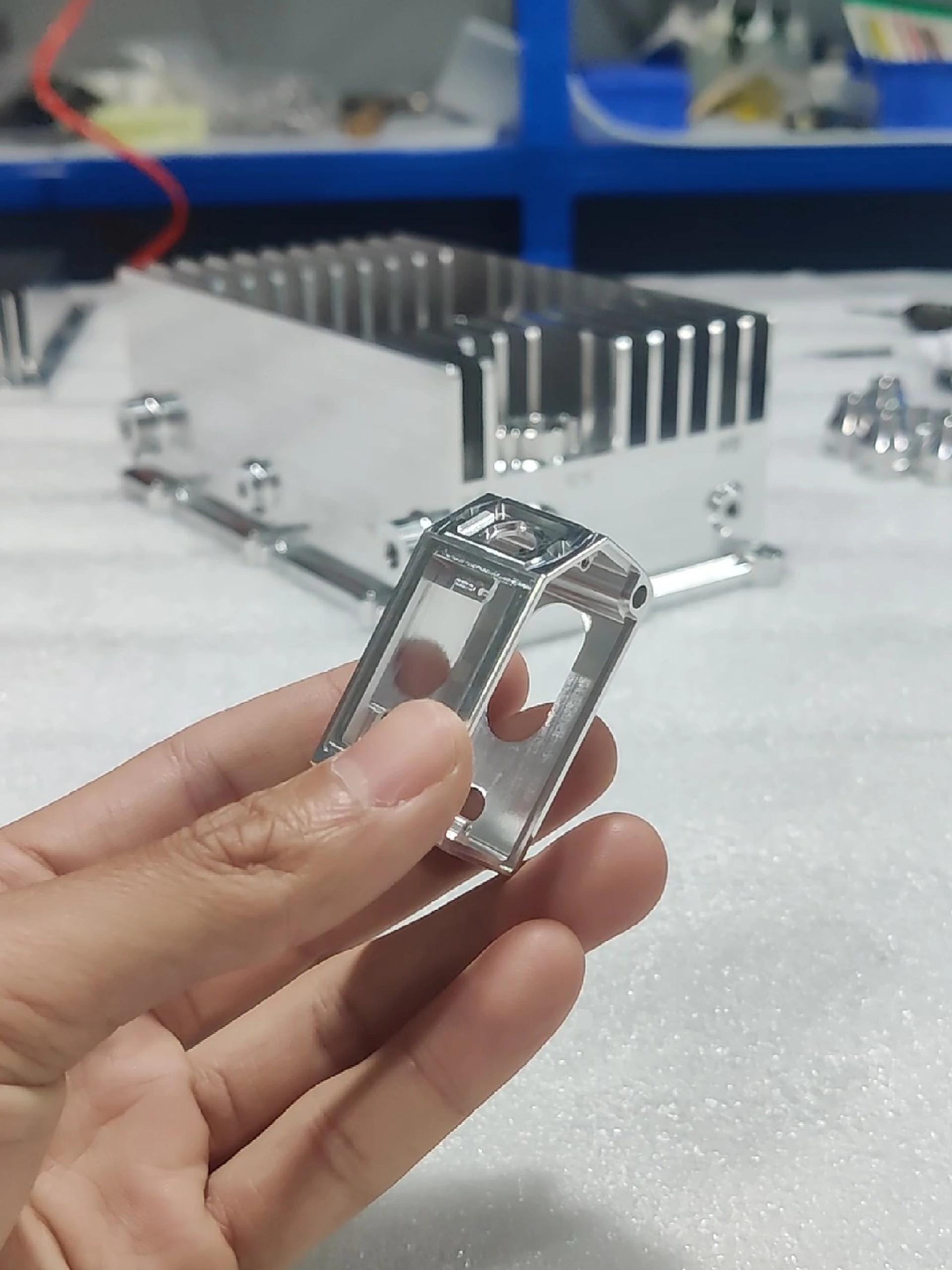

The skeletonized aluminum frame shown in the video is a masterclass in challenging these conventions. It is a piece of functional art—a structural component that has been intelligently lightweighted for the maximum possible strength-to-weight ratio. Every gram of non-essential material has been strategically carved away, leaving behind a framework that is not only incredibly strong and light but also visually stunning.

This is where advanced engineering meets true craftsmanship. Creating parts like this isn’t about simply removing metal; it’s about understanding the forces at play and having the manufacturing capability to execute a complex design flawlessly. For engineers and product designers in demanding fields like aerospace, motorsport, robotics, and high-end electronics, this approach opens up new frontiers in performance and design.

Let’s explore the principles behind this design philosophy and the advanced manufacturing techniques required to bring such an extraordinary component to life.

The Engineering Principle: Intelligent Lightweighting

“Lightweighting” is a core goal in almost every advanced engineering sector. The benefits are profound:

- In aerospace, lighter components mean better fuel efficiency and higher payload capacity.

- In automotive and motorsport, reduced mass leads to faster acceleration, better handling, and improved braking.

- In robotics, lighter arms and end-effectors reduce the moment of inertia, allowing for faster, more precise movements with less power consumption.

- In portable electronics, it means a more user-friendly and premium-feeling device.

However, true lightweighting is not just about using a lighter material. It’s about optimizing the geometry of the part itself. Finite Element Analysis (FEA) software allows designers to simulate the stresses a part will endure in operation. This analysis reveals which areas of the component are under high stress and which are carrying very little load.

A skeletonized design is the physical manifestation of this data. We strategically machine away the low-stress material, creating pockets and through-holes, while leaving a robust “skeleton” of material exactly where it’s needed to maintain structural integrity. The result is a part that is significantly lighter than its solid counterpart but sacrifices little to no functional strength.

The “How”: A Symphony of Technology and Technique

Achieving this level of functional art requires a manufacturing process that is as sophisticated as the design itself. This is a multi-stage journey that relies on cutting-edge technology and meticulous human skill.

1. Complex 5-Axis Machining: The Key to Geometric Freedom

A part with internal pockets, angled surfaces, and features on multiple faces, like the one in the video, would be nearly impossible to create efficiently or accurately with traditional 3-axis machining. This is where the power of 5-axis CNC machining is essential.

A 5-axis machine can move a cutting tool across the X, Y, and Z linear axes while simultaneously rotating on two additional axes (A and B). This allows the tool to approach the workpiece from any direction in a single setup.

- Uncompromised Structural Integrity: The ability to machine the entire part in a single clamping is crucial. Every time a part is moved and re-fixtured, there is a small but real risk of introducing alignment errors. By completing all the complex cuts in one continuous operation, we ensure that every feature is perfectly located relative to the others, preserving the geometric and structural integrity of the design.

- Accessing the “Impossible”: 5-axis machining is the only way to effectively create the deep internal pockets and complex, angled through-holes that characterize skeletonized designs, all while maintaining a flawless surface finish.

2. Meticulous Deburring & Polishing: Where Science Meets Art

The brilliant, mirror-like finish on this component is not just for show. It serves a critical engineering purpose.

In metallurgy, it’s known that microscopic scratches, tool marks, and sharp edges can act as “stress risers.” These are points where stress can concentrate, potentially leading to the formation of micro-cracks and, eventually, fatigue failure over time. A highly polished, smooth surface is inherently stronger and more resistant to fatigue.

Achieving this finish is a painstaking process:

- Meticulous Deburring: After machining, every sharp edge is carefully deburred by hand under magnification. This first step is vital for safety and for preparing the surface for polishing.

- Multi-Stage Finishing: The part then undergoes a multi-stage polishing process, using progressively finer abrasive compounds to remove any trace of machining marks.

- Final Buffing: The final stage uses specialized buffing wheels and polishing compounds to bring the aluminum to a mirror-like sheen.

This process is a craft that requires a steady hand and a deep understanding of how the material behaves. The result is a finish that not only looks incredible but also enhances the component’s durability and lifespan.

3. From a Single Prototype to Scalable Production

It’s one thing to create a single, perfect part. It’s another to deliver that same level of quality consistently, whether the order is for one part or one thousand. We ensure scalable precision through a robust quality system.

- Process Control: The digital CAM program that guides the CNC machine ensures that the cutting paths are identical every time.

- CMM Inspection: We use Coordinate Measuring Machines (CMM) to verify that the critical dimensions of every part match the original CAD model to within microns.

- Consistent Finishing Standards: Our finishing processes are standardized to ensure that the final look and feel of part #1000 is indistinguishable from part #1.

This commitment means you can rely on us for everything from initial functional prototypes to low-volume production runs, confident that the quality will be exceptional every single time.

Conclusion: Elevate Your Design

The skeletonized aluminum frame is more than just a component; it’s a statement. It says that performance does not have to come at the expense of elegance. It proves that with the right design philosophy and advanced manufacturing partner, you don’t have to choose between strength, weight, and beauty.

This is the future of high-performance manufacturing—creating components that not only perform flawlessly under demanding conditions but also elevate the perceived value and aesthetic appeal of the final product.

Looking to push the boundaries of lightweighting and aesthetics in your next design? Let’s build something extraordinary together. Contact our engineering team to discuss how we can bring your most ambitious ideas to life. 🤝