“We thought stamping would be cheaper—but CNC was the smarter choice.”

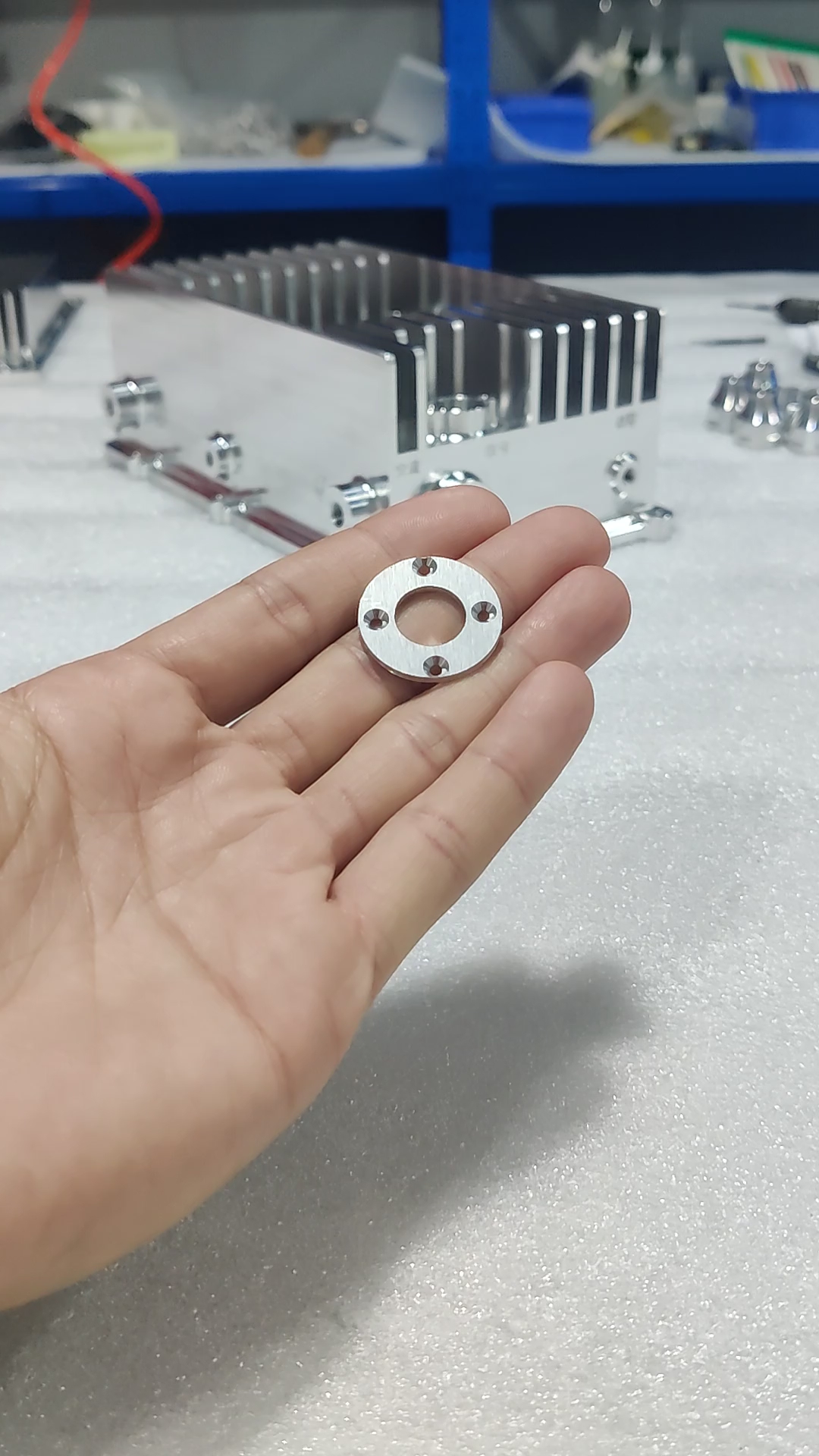

This is a conversation we have frequently. A client recently came to us with a design for a seemingly simple aluminum flange, like the one pictured in the video. Their planned production run was around 100 pieces. Their initial assumption, a very common and logical one, was that for a flat, repeatable part like this, metal stamping would be the most cost-effective method.

On the surface, it makes perfect sense. Stamping is the engine of mass production, capable of punching out identical parts with incredible speed. But as we walked through the total project requirements, the numbers and logistics told a very different story.

This scenario highlights a critical decision point that many engineers, product developers, and procurement managers face: choosing between CNC machining and metal stamping. The “right” choice isn’t always the most obvious one. It requires looking beyond the simplicity of the part and analyzing the project through the lenses of volume, time, cost, and risk.

Let’s break down the strategic differences between these two powerful manufacturing processes and reveal why CNC machining was the undisputed winning path for this low-volume project.

Understanding Metal Stamping: The Power of Mass Production

First, it’s essential to understand what makes metal stamping so effective at what it does. The process is conceptually straightforward: a sheet of metal is placed in a stamping press, and a custom-made tool and die set forms or punches the metal into the desired shape. Think of it as an industrial-grade, ultra-precise cookie cutter.

The Strengths of Stamping:

- Unmatched Speed at Scale: Once the press is running, it can produce parts in seconds or less. For true mass production—tens of thousands to millions of units—its speed is unparalleled.

- Extremely Low Per-Piece Cost (Eventually): Because the cycle time is so short and the process is highly automated, the cost to produce each individual part at high volumes becomes incredibly low.

However, this incredible efficiency comes with a significant catch, one that is often underestimated.

The Catch: The Tool and Die Set

The custom tool and die required for stamping is a highly engineered, extremely durable piece of hardened steel. This tooling is the heart of the stamping process, but it introduces major considerations:

- High Upfront Tooling Cost: The design and fabrication of a custom die is a substantial investment. For a part of even moderate complexity, tooling can cost thousands, and often tens of thousands of dollars. This is a massive capital expenditure that must be made before a single production part is created.

- Long Tooling Lead Time: Creating this tool is not a quick process. It can take anywhere from 4 to 12 weeks, or longer, from final design approval to a production-ready tool.

- Design Inflexibility: Once that hard steel tool is made, your design is essentially locked in stone. If a prototype reveals a design flaw or if market feedback necessitates a change, modifying the tool is incredibly difficult and expensive. Often, a completely new tool must be made, resetting both the cost and the clock.

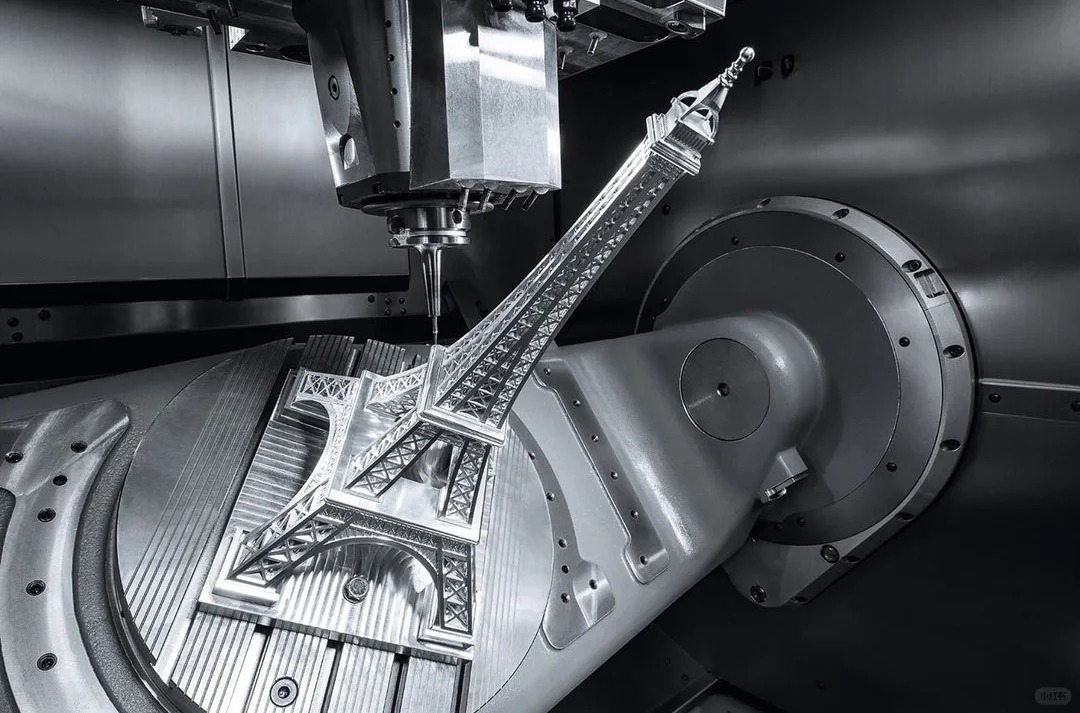

Understanding CNC Machining: The Power of Agility

CNC (Computer Numerical Control) machining takes the opposite approach. It is a subtractive process that starts with a solid block or plate of metal. Guided by a digital CAD file, high-speed cutting tools precisely carve away material to create the final part.

The Strengths of CNC Machining:

- Zero Tooling Cost: This is the most significant financial advantage for low-to-mid volume projects. There is no custom die to create. The process goes directly from a digital file to a physical part, eliminating the huge upfront investment.

- Speed to First Part: Without the multi-week delay for tooling, production can begin almost immediately. You can have a first article or even a full short run of parts in your hands in a matter of days.

- Unmatched Design Flexibility: Need to change a hole diameter or adjust a mounting location? It’s as simple as editing the CAD model and updating the machine’s program. This agility is invaluable for iterative design, prototyping, and responding to changing requirements without incurring massive costs or delays.

- Guaranteed Precision: CNC machining can hold extremely tight tolerances, often much tighter than what is practical with stamping, ensuring perfect fit and function every time.

The Real Crossover Point: It’s More Than Just a Number

The conventional wisdom suggests there’s a “crossover point”—a specific quantity where stamping becomes cheaper than machining. While this is true in a purely per-part cost analysis, that simplistic view ignores three critical business factors: Time, Total Cost, and Risk.

1. The Cost of Time (Time-to-Market)

For the client with the flange, getting their product assembled and to market quickly was a top priority.

- Stamping Path: 6-8 week lead time for the die + 1 week production = 7-9 weeks to finished parts.

- CNC Machining Path: 0 weeks for tooling + 1-2 weeks production = 1-2 weeks to finished parts.

By choosing CNC, the client could get their product to market over a month earlier. That extra month of sales, market presence, and customer feedback has a real, tangible value that often outweighs any potential savings on the per-part cost.

2. The Cost of the Project (Total Cost of Ownership)

Let’s run a hypothetical cost analysis for the 100-piece flange run:

- Stamping Path:

- Tooling Cost: $5,000 (a conservative estimate)

- Per-Piece Cost: $1.50

- Total Project Cost: $5,000 + (100 x

1.50)=∗∗1.50)=∗∗5,150**

- CNC Machining Path:

- Tooling Cost: $0

- Per-Piece Cost: $30

- Total Project Cost: $0 + (100 x

30)=∗∗30)=∗∗3,000**

In this real-world scenario, CNC machining was over 40% cheaper in total project cost. The per-part price of stamping was lower, but that advantage was completely erased by the massive upfront tooling investment required for such a small run.

3. The Cost of Risk (Design Changes)

Imagine if, after receiving the first 100 flanges, the client discovered they needed to add a countersink to the mounting holes.

- Stamping Path: The hardened steel die would need to be sent out for costly and time-consuming modification, if possible at all. In many cases, a new tool would be required.

- CNC Machining Path: This is a simple programming change that adds minimal cost and time to the next production run.

For prototyping, new product introductions, or any project where the design is not 100% validated and frozen, CNC machining removes a massive amount of financial and schedule risk.

Conclusion: Choose the Smartest Path, Not Just the Obvious One

Don’t judge the process by the simplicity of the part. For low-volume projects, even for seemingly “perfect for stamping” components, CNC machining frequently saves significant time, money, and hassle. It is more than just a prototyping tool; it is a powerful and strategic solution for agile, on-demand, low-to-mid volume manufacturing.

The Takeaway Checklist:

- Choose Stamping When: Your volume is in the tens of thousands or higher, your design is absolutely finalized, and you can afford the upfront time and cost for tooling.

- Choose CNC Machining When: Your volume is anywhere from 1 to ~10,000 units, speed-to-market is critical, you want to avoid a large capital investment in tooling, and your design may require future flexibility.

Choosing the right manufacturing method is a critical step in the success of your project. Let’s discuss the smartest, most cost-effective path for your specific needs. 🤝