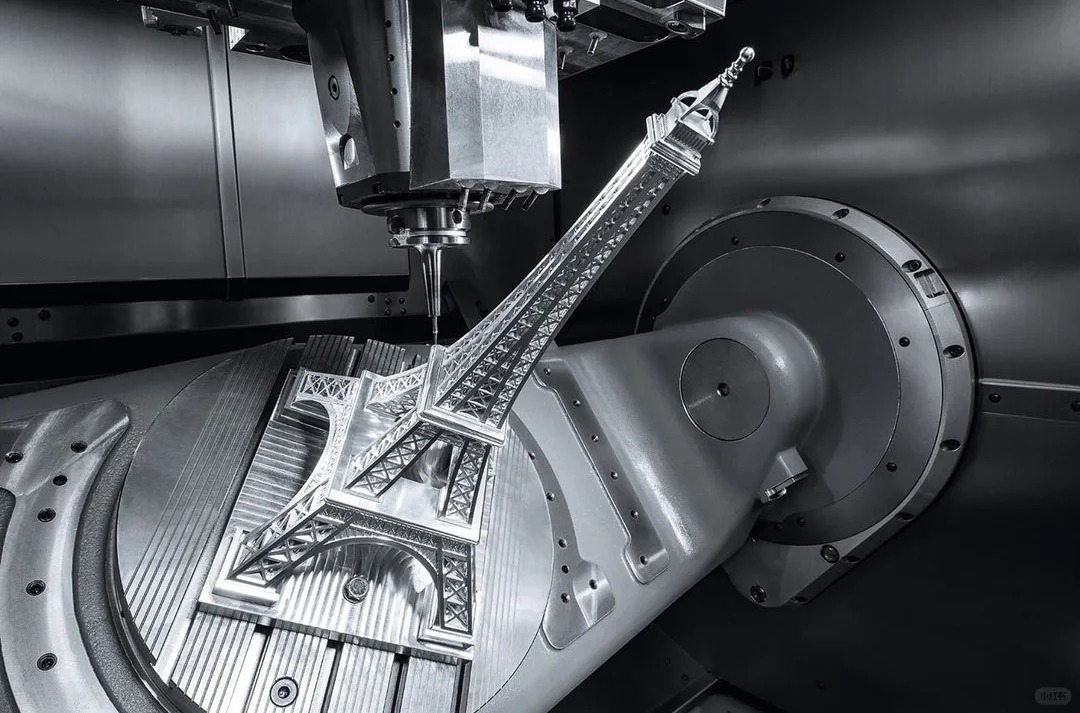

A successful product is rarely a single, monolithic part. It is an ecosystem—a carefully orchestrated assembly of precision components working in perfect harmony. From structural frames and mounting plates to intricate pins and custom fasteners, each piece plays a critical role. As the collection of custom CNC-machined aluminum parts in the video illustrates, the quality of the final product is determined not just by the quality of its individual parts, but by how seamlessly they integrate.

This brings a critical strategic question to the forefront for engineers, product developers, and project managers: what is the best way to source these components? Is it better to find individual specialist shops for each part, or to consolidate manufacturing with a single, highly capable partner?

While spreading the work across multiple vendors may seem like a way to diversify or find the lowest price on each line item, this fragmented approach often introduces hidden costs, risks, and delays that can jeopardize an entire project. The most successful and streamlined product development cycles are built on the foundation of a one-stop manufacturing partner.

Let’s explore the pitfalls of a fragmented supply chain and uncover the profound advantages that a single-source partnership brings to any multi-component assembly.

The Hidden Dangers of a Fragmented Supply Chain

You’ve likely experienced this scenario: you’ve sourced five different machined parts from three different vendors. Each part arrives with a quality report showing it is “in-spec” and meets the drawing’s tolerances. Yet, when you try to assemble them, they don’t fit. The holes don’t align perfectly, there’s an unexpected binding, or a critical gap is too large. This is where the logistical and engineering nightmare begins.

This common problem is a symptom of a fragmented supply chain, which introduces several key risks:

1. The Tolerance Stack-Up Trap:

This is the most critical technical risk. Every dimension on a part has an acceptable tolerance (e.g., ±0.05mm). When multiple parts are assembled, their individual tolerances can “stack up” in an additive way. A hole on Part A might be at the high end of its positional tolerance, while the mating pin on Part B is at its low end. While both parts are technically “correct” according to their individual drawings, their combined deviation can lead to a failed assembly. A single manufacturing partner machines the entire ecosystem of parts with the final assembly in mind, understanding these critical mating interfaces and managing tolerances holistically to guarantee a perfect fit.

2. Inconsistent Quality and Finish:

No two machine shops are exactly alike. They use different machines, different tooling, different CAM software, and have different standards for quality and surface finishing. Sourcing parts from multiple vendors often results in a final product that looks mismatched. The sheen of the aluminum might be different, the deburring quality might vary, and the overall feel can be inconsistent—subtly communicating a lack of quality control to the end user. A single partner ensures every component receives the same high standard of machining and finishing, resulting in a cohesive, professional, and premium final product.

3. The Logistical Nightmare:

For a project manager, juggling multiple vendors is a significant drain on time and resources. It means managing:

- Multiple purchase orders and invoices.

- Separate communication channels for updates and questions.

- Different lead times and production schedules.

- Multiple shipping and receiving points.

This complexity increases the chances of miscommunication, delays, and administrative overhead, pulling focus away from core project development.

4. The “Blame Game” When Things Go Wrong:

When that assembly fails, who is at fault? Vendor A will point to their inspection report and blame Vendor B. Vendor B will do the same. This finger-pointing leads to project delays and frustrating disputes, with your team caught in the middle.

The Single-Source Solution: A Partnership in Precision

Consolidating your manufacturing with a one-stop partner, like the one responsible for the harmonious set of parts in the video, transforms the process from a series of transactions into a true strategic partnership. It directly solves the problems listed above.

1. Guaranteed Fit & Assembly-Level Precision

A single-source partner isn’t just making parts; they are building your assembly. We take responsibility for the entire component ecosystem. This means our engineers and machinists are constantly thinking about how Part A interfaces with Part B. We can adjust machining strategies and hold tighter tolerances on critical mating features to ensure that tolerance stack-up is never an issue. The result: a perfect fit, every time, right out of the box.

2. Unwavering Consistency in Quality and Finish

When we manufacture your complete set of components, you get the benefit of a single, unified quality standard. From the raw material certification and first-article inspection to the final surface finish and deburring, every part undergoes the same rigorous process. This ensures your final product has the consistent, high-end look and feel that builds brand trust and customer satisfaction.

3. A Radically Streamlined Supply Chain

Imagine replacing the logistical chaos of multiple vendors with the simplicity of one. A single-source partnership means:

- One Point of Contact: A dedicated project manager who understands your entire project.

- One Purchase Order: Simplified procurement and accounting.

- One Quality Standard: No surprises or inconsistencies.

- One Coordinated Delivery: All your components arrive together, ready for assembly.

This streamlined approach radically reduces risk, minimizes administrative burden, and accelerates your time-to-market.

4. True Partnership and Accountability

When you work with a single partner, there is no blame game. We own the outcome. We are fully accountable for the fit, function, and quality of the entire component set. This accountability fosters a deeper level of collaboration. Our engineers can provide valuable Design for Manufacturability (DfM) feedback that not only improves individual parts but also optimizes the entire assembly for cost, performance, and ease of production.

Building a Foundation for Success

The decision of how to source your custom machined components is one of the most impactful choices you can make in the product development process. While it may be tempting to chase the lowest price on each individual part, the hidden costs of a fragmented supply chain in terms of time, risk, and inconsistent quality can be immense.

By choosing a one-stop manufacturing partner, you are not just buying parts; you are investing in a seamless, efficient, and reliable supply chain. You are investing in the certainty that your components will work together as intended, allowing your team to focus on innovation and bringing a superior product to market faster.

Planning a multi-component assembly for your next project? Let’s move beyond transactional manufacturing. Let’s build a seamless, high-precision supply chain together. 🤝