1. What is CNC Machining? The Power of Precision Control

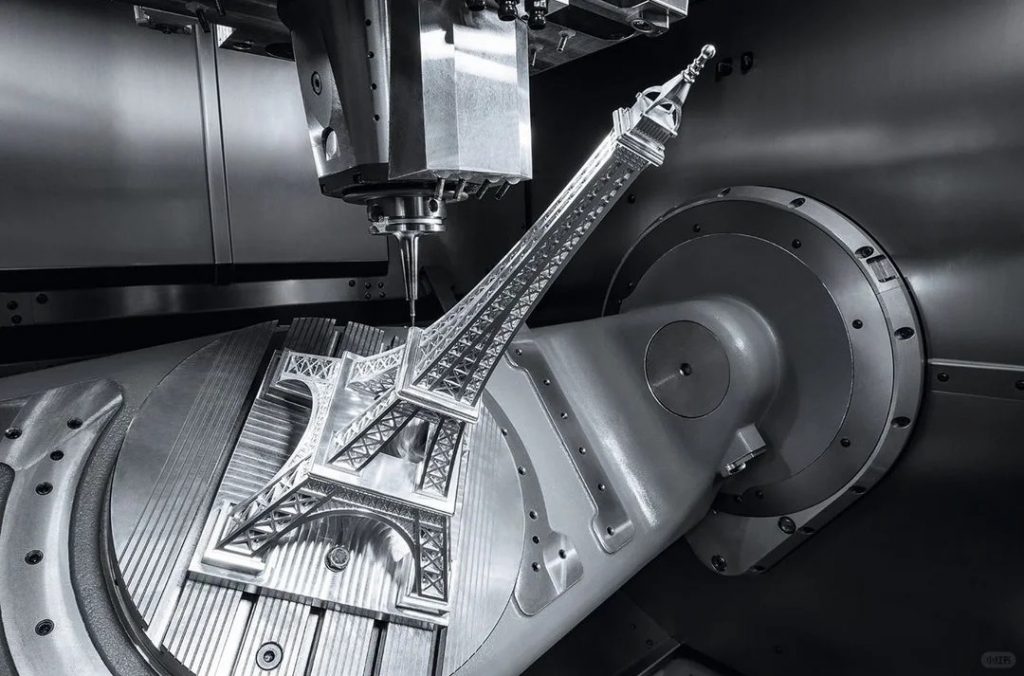

CNC machining is a subtractive manufacturing process that uses computer-controlled machinery to remove material from a workpiece, shaping it into a desired form. Digital design files (like CAD – Computer-Aided Design models) are translated into machine instructions (G-code) that dictate the tools’ movements, speeds, and feeds. This automation eliminates manual intervention, leading to:

- Unparalleled Precision: Machines can achieve incredibly tight tolerances, often measured in microns.

- Exceptional Repeatability: Once programmed, a CNC machine can produce identical parts consistently, batch after batch.

- Complex Geometries: Intricate shapes and features that are difficult or impossible with manual methods become feasible.

Common CNC processes include milling (using rotating cutting tools), turning (rotating the workpiece against a cutting tool), drilling, grinding, and more.

2. Key Advantages of Leveraging CNC Machining Services

Opting for CNC machining services offers a multitude of benefits for businesses looking to innovate and optimize their production:

- High Accuracy and Consistency: As mentioned, the computer-driven nature ensures every part meets exact specifications, critical for components that need to fit and function perfectly.

- Material Versatility: CNC machines can work with a vast array of materials, including various plastics (ABS, Polycarbonate, Nylon, PEEK, Acrylic, etc.), metals (Aluminum, Steel, Brass, Titanium), and even wood or composites. This makes it suitable for diverse industrial design applications.

- Speed and Efficiency: Automated processes significantly reduce production time compared to manual methods. This is invaluable for rapid prototyping, allowing for quick design iterations, and for efficient low-to-medium volume production runs.

- Cost-Effectiveness for Complexity and Volume: While initial setup can be a factor, CNC machining becomes highly cost-effective for complex parts due to reduced labor and minimal errors. It’s also efficient for small to medium production runs where tooling costs for other methods (like injection molding) might be prohibitive for initial batches.

- Scalability: From a single prototype to thousands of units, CNC machining can scale to meet your demand, ensuring a smooth transition from product development to market entry.

3. Applications: Where CNC Machining Shines

The precision and versatility of CNC machining make it indispensable across numerous industries:

- Prototyping: Creating functional prototypes for plastic products, enclosures, and mechanical parts to test form, fit, and function.

- Custom Parts & Tooling: Manufacturing bespoke components, jigs, fixtures, and even molds for other manufacturing processes.

- Aerospace & Automotive: Producing high-strength, lightweight components with critical tolerances.

- Medical Devices: Crafting intricate surgical instruments and implantable devices from biocompatible materials.

- Electronics: Machining custom enclosures, heat sinks, and precision components.

- Consumer Products: Developing durable and aesthetically pleasing parts for a wide range of goods.

4. Partnering for Success: Choosing Your CNC Machining Provider

When selecting a CNC machining service, look for a partner who offers more than just parts. At Palinetech, we combine state-of-the-art CNC technology with deep expertise in materials and manufacturing processes. We understand the journey from an industrial design concept to a finished plastic product or a precision-engineered component.

We offer:

- Consultative Approach: We work closely with you to understand your project requirements and optimize your designs for manufacturability.

- Wide Range of Materials: Expertise in machining various plastics and metals.

- Quality Assurance: Rigorous inspection processes to ensure every part meets your standards.

- Seamless Integration with Design Services: If you’re also leveraging our plastic product industrial design services, we ensure a smooth transition from design to prototyping and production.

Conclusion: Elevate Your Manufacturing with CNC Machining

CNC machining is a transformative technology that empowers businesses to create high-quality, precise, and complex parts efficiently. Whether you’re innovating with new plastic products or require reliable components for industrial use, CNC offers a robust solution.

Ready to bring your designs to life with precision and efficiency? Contact me today to discuss your CNC machining project or learn how our integrated industrial design and manufacturing services can benefit you!