1. A Quick Look at the Contenders

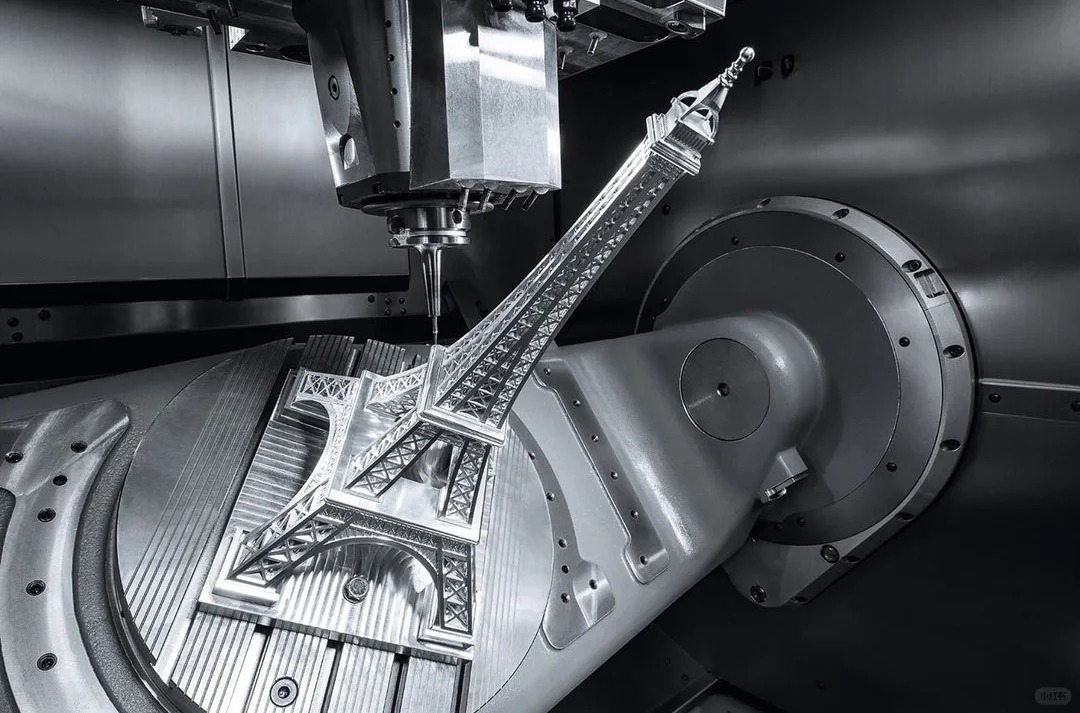

- CNC (Computer Numerical Control) Machining: A subtractive process where material is precisely removed from a solid block (e.g., plastic, metal) using computer-controlled cutting tools to achieve the desired shape.

- 3D Printing (Additive Manufacturing): An additive process where parts are built layer-by-layer from a digital model. Common types include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

- Injection Molding: A formative process where molten plastic is injected under high pressure into a custom-made mold (tool). Once cooled, the part is ejected.

2. Comparing Manufacturing Methods: Key Criteria

Let’s compare these methods across factors crucial for product development and production:

| Feature | CNC Machining | 3D Printing (General) | Injection Molding |

|---|---|---|---|

| Complexity & Precision | Excellent for very high precision & complex geometries (especially with 5-axis). Smooth surface finish. | Good for complex, organic shapes. Precision varies by tech (SLA/SLS better than FDM). Layer lines may be visible. | Excellent for high precision & repeatability once mold is perfect. Complexity limited by mold design (e.g., undercuts add cost). |

| Material Variety | Very wide range of plastics (ABS, PC, Nylon, PEEK, Acrylic, Delrin, etc.) and metals. Uses production-grade materials. | Growing range, but often specific to the 3D printing technology. Some engineering-grade plastics available, but properties may differ from molded/machined counterparts. | Vast range of thermoplastics and some thermosets. Excellent for production-grade materials. |

| Speed for Prototypes | Fast (hours to days) for functional, real-material prototypes. | Very fast (hours to days), especially for early-stage concept models. | Slowest due to long mold creation time (weeks to months). |

| Speed for Production | Good for low-to-medium volumes. Setup time per part is minimal once programmed. | Generally slower for mass production due to layer-by-layer build. Better for very small batches or customized one-offs. | Fastest for high-volume production once mold is ready (seconds per part). |

| Cost – Tooling | No specific “tooling” cost in the molding sense. Programming & setup time is the upfront effort. | Minimal to no tooling cost. | Very high upfront tooling (mold) cost. |

| Cost – Per Part | Moderate. More expensive than molding at high volumes, but cheaper than molding for low volumes. | Can be high for larger parts or higher-resolution prints. Competitive for very small quantities/one-offs. | Very low per-part cost at high volumes, making it ideal for mass production. |

| Volume Suitability | Prototypes, one-offs, low-to-medium volume production (tens to thousands). | Best for prototypes, one-offs, highly customized small batches. | Best for medium-to-high volume production (thousands to millions). |

| Part Strength & Properties | Excellent. Parts retain bulk material properties. Ideal for functional testing and end-use parts. | Varies. FDM parts can have anisotropic (direction-dependent) strength. SLA/SLS can produce strong parts. Material properties may not fully match traditional methods. | Excellent. Parts generally have isotropic and strong mechanical properties. |

| Design Changes | Easy and relatively inexpensive to implement. Modify CAD, reprogram. | Very easy to implement. Modify CAD, reprint. | Very expensive and time-consuming to modify molds. |

3. When is CNC Machining the Optimal Choice?

CNC machining truly excels in several scenarios:

- High-Quality Prototypes: When you need prototypes made from the exact production-intent plastic (or metal) for rigorous functional testing, form/fit validation, or pre-production samples.

- Tight Tolerances and Smooth Finishes: If your design demands high precision, intricate details, and excellent surface quality that 3D printing might struggle to achieve without post-processing.

- Low-to-Medium Volume Production: For production runs that are too small to justify the high cost of injection mold tooling, but too large or demanding for 3D printing (e.g., a few hundred to several thousand parts).

- Complex Parts Not Suitable for Molding: For geometries that would require extremely complex and expensive molds, or parts that cannot be easily molded due to undercuts or internal features.

- Bridge Tooling/Production: To get products to market quickly while injection molds are being manufactured, or for initial market testing before committing to mass production.

- Frequent Design Iterations: When designs are still evolving and changes are expected, CNC machining allows for flexibility without incurring re-tooling costs.

- Material Specificity: When the chosen plastic (e.g., PEEK, Delrin, specific Nylon grades) is best processed or achieves optimal properties through machining.

4. How Paulinetech Helps You Navigate the Options

At Paulinetech, we understand that choosing the right manufacturing process is as critical as the industrial design itself. Our expertise spans:

- Plastic Product Industrial Design: We help you design products with manufacturability in mind, considering the best process from the outset.

- CNC Machining Services: We offer state-of-the-art CNC machining for both prototyping and production of your custom plastic parts.

- Informed Guidance: We can analyze your project requirements – design complexity, material needs, volume, budget, and timeline – to help you determine if CNC machining, or potentially another method, is the most suitable path. Our goal is your project’s success.

Conclusion: Making an Informed Manufacturing Decision

No single manufacturing method is universally superior; the “best” choice depends entirely on your project’s specific needs. By understanding the comparative advantages of CNC machining, 3D printing, and injection molding, you can make strategic decisions that align with your goals for your plastic products.