Heat: it’s the number one enemy of compact, high-performance electronics. As our devices become smaller, faster, and more powerful, the challenge of managing the thermal load they generate becomes exponentially more difficult. From high-power LED drivers and ruggedized computing modules to advanced power supplies and RF amplifiers, dissipating heat effectively is the critical factor that dictates performance, reliability, and lifespan.

For many engineers, the default solution is an off-the-shelf, extruded aluminum heatsink. These are readily available, inexpensive, and for many applications, “good enough.” But in the world of cutting-edge product design, “good enough” is a recipe for compromise.

Standard heatsinks often force a series of frustrating trade-offs: designers are forced to create products around a generic component, valuable space is wasted, and thermal performance is capped by the limitations of the extrusion process.

But what if there was a way to eliminate these compromises entirely?

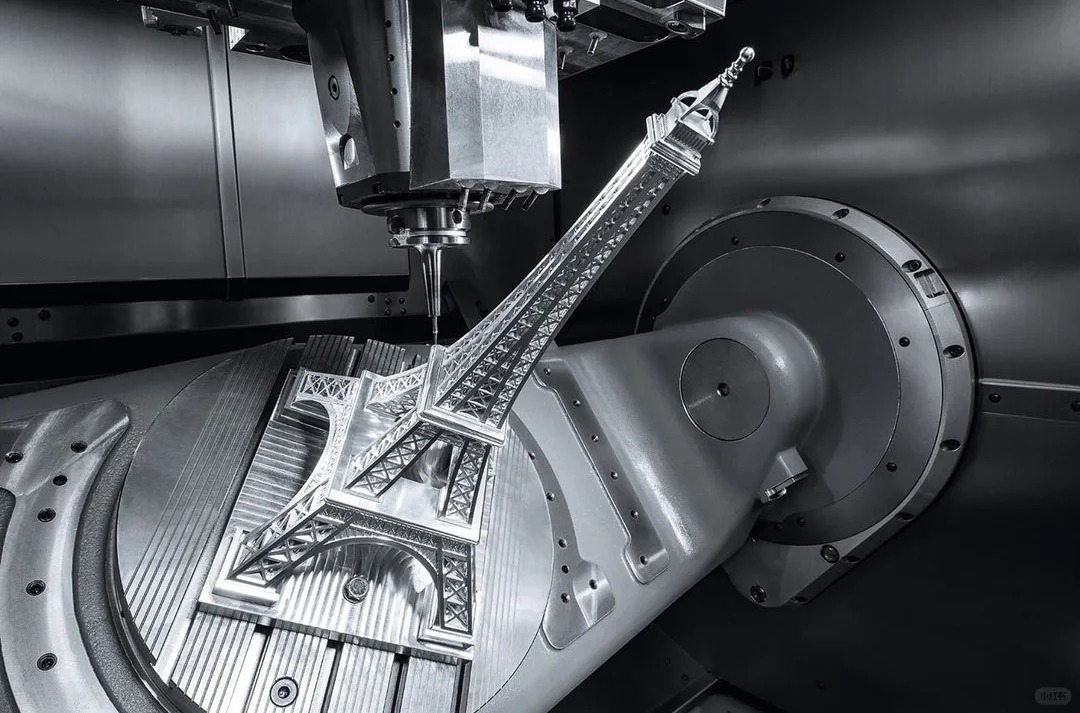

When every degree of temperature and every millimeter of space matters, a custom-machined thermal solution is the only way forward. The component showcased in the video is a prime example of this philosophy in action. This isn’t just a heatsink—it’s an integrated thermal enclosure, a single, monolithic component CNC-machined from a solid block of aluminum to serve as both a high-performance cooling system and a rugged, perfectly-fitting structural housing.

For engineers and designers, this approach means no more trade-offs. It’s the key to achieving peak cooling performance while simultaneously enabling sleek, compact, and robust product design.

The Problem with “Off-the-Shelf”: The Hidden Costs of Standard Heatsinks

Before we explore the custom solution, it’s vital to understand the limitations that engineers so often have to design around. Standard heatsinks, typically made via aluminum extrusion, are created by pushing a heated aluminum billet through a die, much like squeezing toothpaste from a tube. While efficient for mass production, this process imposes significant constraints:

- Inefficient Use of Space: An extruded heatsink has a generic, rectangular footprint. Your custom-designed Printed Circuit Board (PCB), however, is not generic. This mismatch forces you to either select a heatsink that is too large, wasting valuable internal volume, or one that is too small, providing inadequate coverage for all heat-generating components.

- Sub-Optimal Thermal Contact: Effective cooling relies on a perfect, flat interface between the heat source (your processor, FET, or LED) and the heatsink. Off-the-shelf solutions may require messy thermal pads or pastes to bridge gaps, adding thermal resistance and reducing efficiency.

- Limited Fin Geometry: The extrusion process limits the geometry of the cooling fins. There’s a maximum height-to-gap ratio, meaning you can’t make the fins too tall and thin, which limits the total surface area available for heat dissipation.

- Increased Part Count and Assembly Complexity: A standard heatsink is just one part of the puzzle. You still need a separate enclosure, fasteners to mount the heatsink to the PCB, and more fasteners to assemble the enclosure. This increases the bill of materials (BOM), complicates the assembly process, and introduces more potential points of failure.

The CNC Machining Solution: An Integrated Approach to Thermal Management

CNC machining flips the entire manufacturing process on its head. Instead of starting with a 2D profile and extruding it, we begin with a solid 3D block of high-grade, thermally conductive aluminum (like 6061-T6). From this block, we precisely carve away material to create a component that is perfectly tailored to your exact specifications. This subtractive approach unlocks three transformative advantages.

1. Perfect Fit, No Compromise: Geometry Tailored to Your Design

With CNC machining, the heatsink is designed to fit your product, not the other way around.

- Custom Footprints: We can machine the base of the heatsink to perfectly match the outline of your PCB, including cutouts for connectors and mounting holes. This maximizes the use of space and ensures a clean, integrated final assembly.

- Targeted Cooling: We can machine raised mounting pads or pedestals that make direct, perfect contact with your specific heat-generating components. This eliminates the need for thick, inefficient thermal interface materials and ensures the most direct possible path for heat to escape.

2. More Fins, More Cooling: Superior Thermal Performance

The single most important factor in a passive heatsink’s performance is its surface area. More surface area means more contact with the surrounding air and faster heat dissipation.

- Ultra-Thin, High-Density Fins: CNC machining is not bound by the same aspect-ratio limitations as extrusion. We can create significantly thinner, taller, and more densely packed fins. This dramatically increases the total surface area within a given volume, leading to a massive boost in cooling efficiency compared to a standard heatsink of the same size.

- Optimized Fin Geometries: We can go beyond simple straight fins. The process allows for the creation of complex pin-fin arrays, tapered fins, or other intricate geometries that can be optimized through thermal simulation (CFD analysis) to create ideal airflow patterns and maximize convective cooling.

3. Cooling + Structure in One: The Integrated Enclosure Advantage

This is the most powerful benefit of the custom-machined approach. The heatsink is no longer just a passive component you attach to your product; it becomes a core part of your product’s structure.

- Reduced Part Count: By machining mounting points, standoffs, and enclosure walls directly into the single block of aluminum, we eliminate the need for a separate case and a host of fasteners. This simplifies your BOM, streamlines your supply chain, and makes assembly faster and more reliable.

- Enhanced Durability: A monolithic component machined from a solid block is inherently stronger and more rigid than a multi-part assembly. This makes it ideal for products that need to withstand shock, vibration, and harsh environmental conditions.

- Compact and Sleek Design: Integrating the heatsink and enclosure allows for a much smaller and more elegant final product. The functional cooling fins can become a deliberate, industrial design feature, communicating the product’s high-performance nature.

Conclusion: Stop Designing Around the Problem

For too long, thermal management has been seen as a problem to be solved with an off-the-shelf component, forcing engineers to compromise on their product’s size, performance, and aesthetics. Custom CNC machining reframes the challenge entirely. It transforms the heatsink from an afterthought into a foundational, multi-functional component that actively enhances every aspect of the final product.

By investing in an integrated thermal enclosure, you are not just buying a cooling solution. You are investing in:

- Superior Performance: Lower operating temperatures, leading to higher efficiency and reliability.

- Greater Design Freedom: The ability to create compact, powerful, and beautiful products.

- A Simpler, More Robust Assembly: Fewer parts, less complexity, and enhanced durability.

Struggling with thermal management in your next build? Stop designing around the limitations of standard parts. Let’s design a custom-machined solution that perfectly fits your vision. Contact us today to see how we can solve it together. 🤝