1. The CNC Machining Workflow: A Step-by-Step Overview

Understanding the process behind CNC machining can help appreciate its precision and efficiency:

- Step 1: CAD Model Creation: It all begins with a 2D or 3D Computer-Aided Design (CAD) model. This digital blueprint precisely defines the geometry, dimensions, and features of the desired part. For clients utilizing our plastic product industrial design services, this is often the direct output of the design phase.

- Step 2: CAM Programming: The CAD file is then imported into Computer-Aided Manufacturing (CAM) software. Here, a skilled programmer or engineer plans the machining strategy. This involves selecting appropriate cutting tools, defining toolpaths, setting cutting speeds and feeds, and generating the G-code – the machine-readable instructions that will guide the CNC machine.

- Step 3: Machine Setup: Before machining begins, the raw material (e.g., a block of ABS, Polycarbonate, Aluminum) is securely fixtured onto the CNC machine bed. The cutting tools are loaded into the machine’s tool holder, and the machine is calibrated to ensure precise alignment.

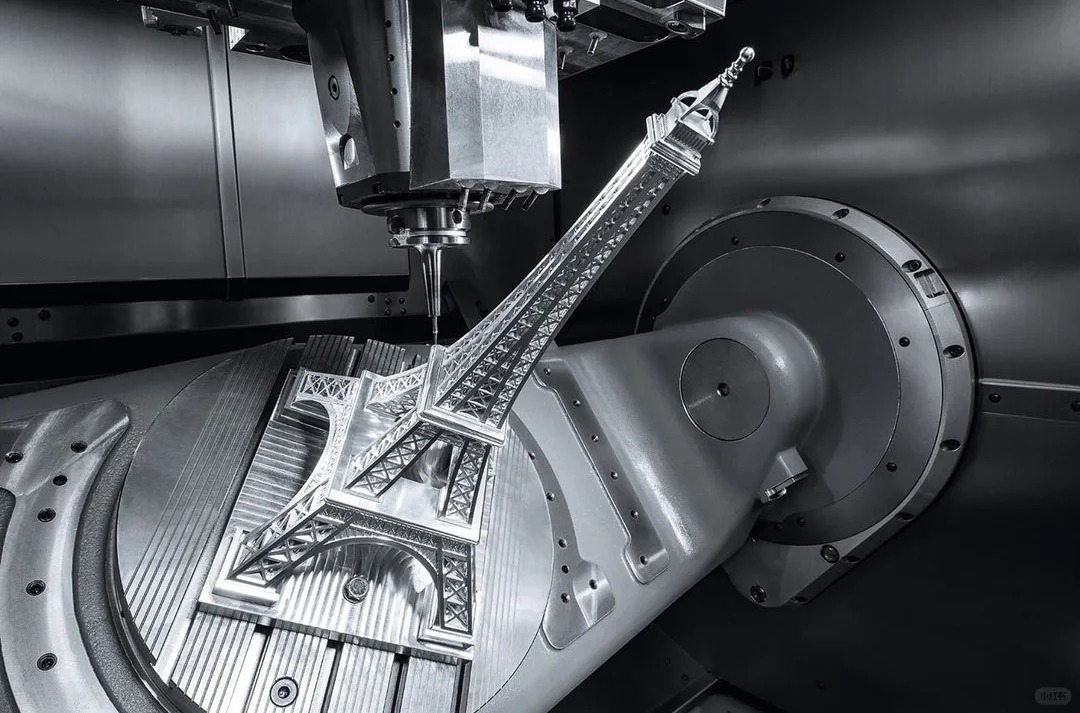

- Step 4: Machining Execution: The G-code is loaded into the CNC controller. The machine then autonomously executes the programmed operations, precisely removing material layer by layer to achieve the final shape. This can involve processes like milling, turning, drilling, or tapping.

- Step 5: Quality Control and Finishing: Once machining is complete, the part is inspected to ensure it meets the specified tolerances and design requirements. Depending on the application, further post-processing steps like deburring, polishing, anodizing (for metals), or painting may be applied.

2. CNC Machining for Rapid Prototyping: Validating Your Designs Quickly

For businesses engaged in plastic product industrial design, rapid prototyping is crucial. CNC machining offers significant advantages in this phase:

- Speed and Accuracy: CNC can produce highly accurate prototypes directly from CAD files in a matter of hours or days, far quicker than traditional tooling methods.

- Real-Material Prototypes: Unlike some additive methods, CNC allows prototypes to be made from the actual production-intent materials (e.g., specific grades of ABS, PC, Nylon). This is vital for testing functional properties like strength, flexibility, and chemical resistance.

- Iterative Design: The speed of CNC prototyping enables designers to quickly test, evaluate, and refine their concepts. Multiple iterations can be produced and assessed, leading to a more optimized final product.

- Form, Fit, and Function Testing: CNC prototypes are ideal for verifying how parts assemble, how they feel (ergonomics), and how they perform their intended function before committing to expensive production tooling.

3. CNC Machining for Production: Precision Parts, On Demand

Beyond prototyping, CNC machining is a robust solution for low-to-medium volume production runs and for creating high-precision end-use parts:

- Consistent Quality: The automated nature of CNC ensures high repeatability, meaning every part produced is virtually identical to the first, maintaining tight tolerances across the entire batch.

- Complex Geometries: CNC machines can create intricate shapes and features that are essential for many modern plastic products and industrial components.

- Cost-Effective for Smaller Volumes: For production quantities that don’t yet justify the high upfront costs of injection molding tools, CNC machining offers a cost-effective alternative. It’s also excellent for “bridge tooling” – producing initial market-ready parts while mass production tools are being developed.

- Customization: CNC is perfect for producing custom parts or variations of a standard design without the need for extensive retooling.

4. Design for Manufacturability (DFM) in CNC

To get the best results from CNC machining, considering Design for Manufacturability (DFM) principles is key. This involves designing parts in a way that makes them easier, faster, and more cost-effective to machine. Aspects include:

- Choosing appropriate materials for the application and machinability.

- Designing internal radii that can accommodate standard cutting tools.

- Ensuring adequate wall thicknesses.

- Minimizing complex undercuts where possible.

At Paulinetech, our expertise extends to advising on DFM for CNC, ensuring your plastic product designs are optimized for efficient and high-quality manufacturing.

Conclusion: Your Partner from Concept to Component

The CNC machining journey, from a digital CAD file to a precisely manufactured physical part, is a cornerstone of modern product development. Its role in both rapid, real-material prototyping and efficient, high-quality production makes it invaluable, especially for those creating innovative plastic products.

Whether you need a functional prototype to validate your latest industrial design or require a batch of precision-machined plastic components, paulinetech has the technology and expertise. Contact us today to discuss how our CNC machining services can bring your vision to reality.