1. The Challenge: Manufacturing Complex and Custom Designs

Traditional manufacturing methods can struggle when faced with:

- Intricate Geometries: Features like undercuts, complex curves, thin walls, and internal cavities can be difficult or impossible to produce with methods like conventional milling or even some molding techniques without complex, expensive tooling.

- Tight Tolerances: Many advanced applications demand components that fit together perfectly and perform reliably, requiring dimensional accuracy measured in microns.

- One-Offs and Small Batches: Creating custom parts or small production runs can be prohibitively expensive if extensive tooling or setup is required for each unique design.

- Material Specificity: The design might necessitate a specific engineering plastic or metal that isn’t easily processed by all manufacturing techniques.

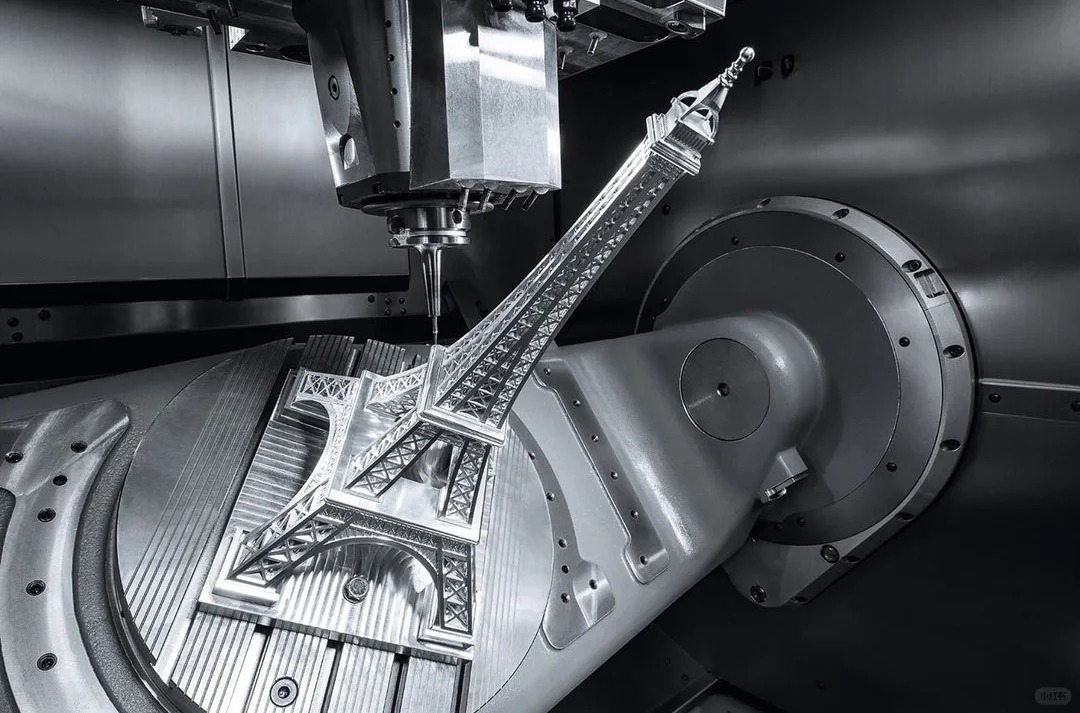

2. How CNC Machining Overcomes Complexity

CNC machining’s inherent characteristics make it uniquely suited to tackle these challenges:

- Multi-Axis Machining (3, 4, and 5-Axis):

- 3-Axis CNC: The cutting tool moves along X, Y, and Z linear axes. Ideal for simpler parts with features accessible from one direction.

- 4-Axis CNC: Adds a rotational axis (A-axis) to the 3 linear axes, allowing the workpiece to be rotated. This enables machining on multiple sides of a part without manual refixturing.

- 5-Axis CNC: Incorporates two rotational axes (A and B, or B and C) along with the three linear axes. This allows the cutting tool to approach the workpiece from virtually any angle, enabling the creation of extremely complex shapes, deep cavities, and smooth, contoured surfaces in a single setup. This significantly reduces setup time and improves accuracy by minimizing part handling.

- Precision and Repeatability: Computer control ensures that tool movements are executed with extreme accuracy, consistently producing parts that meet demanding specifications.

- Subtractive Power: By starting with a solid block of material and precisely removing what’s not needed, CNC can create internal features, pockets, and complex external forms that are challenging for additive methods or molding.

- Software Integration (CAD/CAM): Sophisticated CAM software translates complex 3D CAD models into precise machine instructions, allowing for intricate toolpaths that faithfully replicate the digital design.

3. CNC: The Engine for Customization and Iteration

Beyond just complexity, CNC machining is a powerhouse for customization:

- No Hard Tooling Required for Variations: Unlike injection molding, which requires expensive molds for each design, CNC machining works directly from digital files. This makes it economically viable to produce:

- Unique, one-off parts.

- Small batches of customized components.

- Multiple design iterations during prototyping.

- Rapid Design Changes: If a design needs to be tweaked, only the CAD file and CAM program need updating. New parts reflecting the changes can be machined quickly, facilitating agile product development.

- Tailored Solutions: Whether it’s a custom enclosure for electronics, a specialized jig or fixture, or a unique component for a niche plastic product, CNC can deliver parts perfectly tailored to specific requirements.

4. Material Freedom for Complex Plastic Parts (and More)

CNC machining is compatible with a vast range of materials, which is crucial when specific material properties are needed for complex or custom designs:

- Engineering Plastics: Many advanced plastic products require materials like:

- ABS: Good all-around toughness and impact resistance.

- Polycarbonate (PC): High impact strength and transparency.

- Nylon (PA): Excellent wear resistance and strength.

- PEEK: High-temperature performance and chemical resistance.

- Acrylic (PMMA): Optical clarity and weather resistance.

CNC machines can effectively shape these and many other plastics into intricate forms while maintaining their structural integrity.

- Metals: CNC is also widely used for metals like Aluminum, Steel, Stainless Steel, Brass, and Titanium, offering the same benefits of precision and complexity.

The ability to choose the ideal material and then machine it into a complex shape gives designers immense freedom.

5. When to Choose CNC for Your Complex and Custom Needs

Consider CNC machining when:

- Your plastic product design features intricate details, complex curves, or tight tolerances.

- You need rapid prototypes made from production-intent materials to test complex functionality.

- You require low-to-medium volume production of highly customized parts.

- The cost or lead time for injection mold tooling is prohibitive for your project stage or volume.

- You need to iterate quickly on a complex design.

Conclusion: Realize Your Most Ambitious Designs with CNC

CNC machining empowers businesses and designers to push the boundaries of what’s manufacturable. Its ability to handle complex geometries with precision, coupled with its flexibility for customization and material choice, makes it an indispensable tool for creating innovative plastic products and high-performance components.

Do you have a complex design or a need for custom-machined plastic parts? At Paulinetech, we specialize in CNC machining intricate components and can support your project from industrial design through to production. Contact us to explore the possibilities!