In high-end electronics, the difference between good and great is often measured in microns.

A seamless fit with tolerances below 0.02mm is where true engineering excellence becomes tangible.

Achieving the “Zero-Gap” Standard

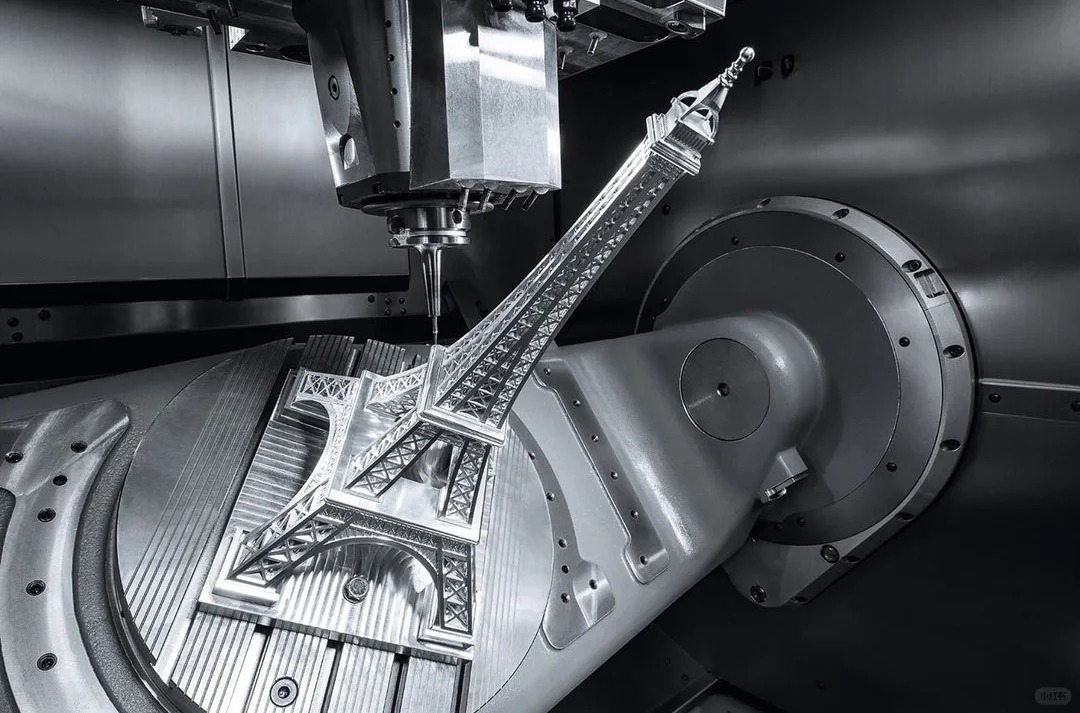

Precision Programming and Machining

We use optimized toolpaths to ensure machining stability and assembly-perfect alignment. This guarantees accuracy at the micron level and consistent repeatability across production runs.

Controlled Surface Finishing

Matte black anodization with uniform thickness is applied, maintaining critical dimensional accuracy. Surface finishing is carefully controlled to prevent deviations that could impact tight-tolerance fits.

Assembly-Level Quality Control

Instead of evaluating only individual parts, we perform full assembly test-fits. This ensures flawless integration and guarantees that products meet functional and aesthetic standards right out of the box.

Why It Matters

For industries where precision and reliability are non-negotiable—such as consumer electronics, medical devices, and industrial equipment—a micron-level difference can define the success of the final product.