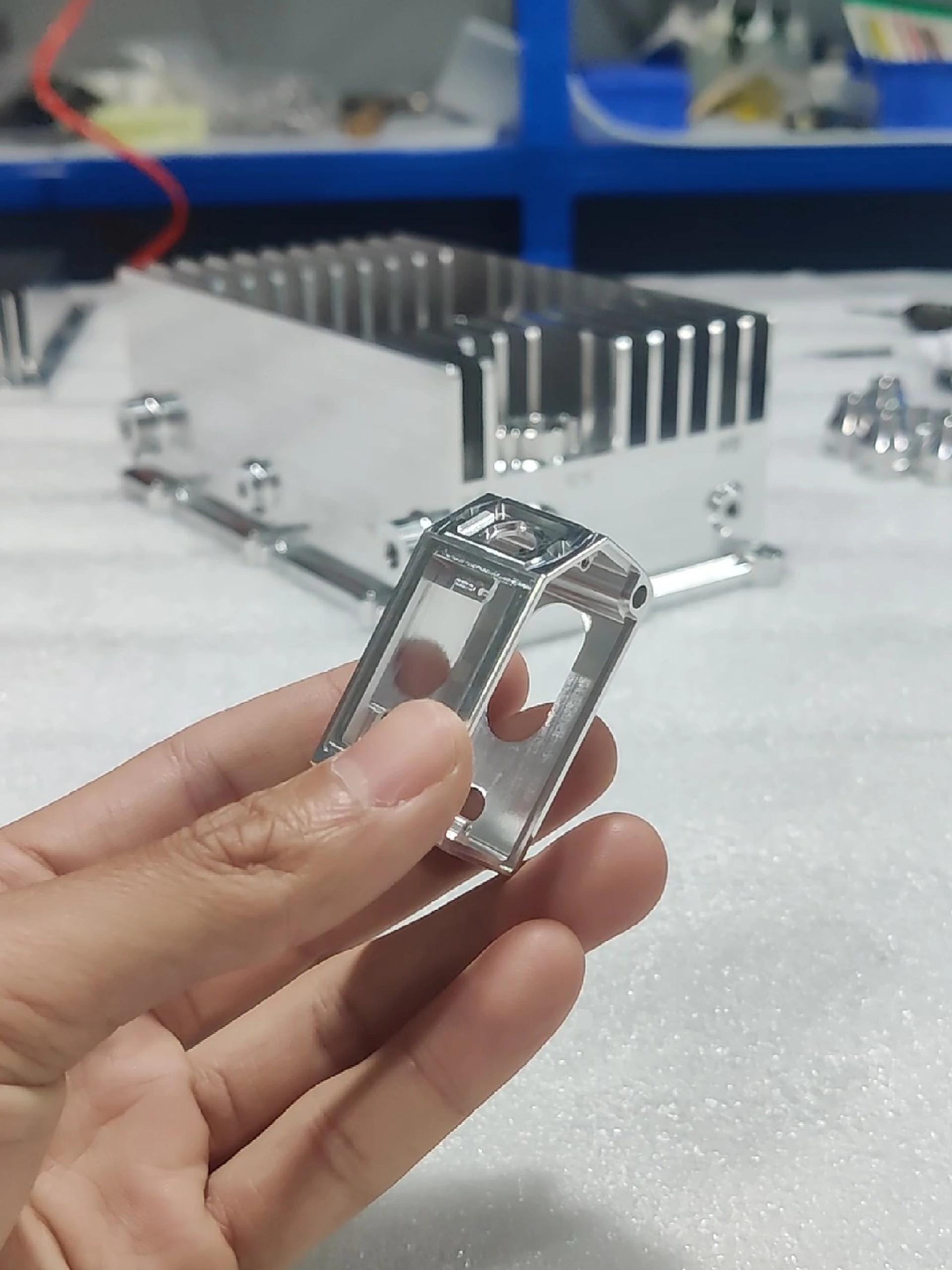

In the world of product design and engineering, looks can be deceiving. At first glance, the custom aluminum plate in the video appears to be a relatively straightforward component. It’s a flat, square part with a few cutouts and holes—a classic candidate for a high-speed, cost-effective manufacturing process like metal stamping.

This is a common assumption, and a logical one. But it’s also incorrect.

This small part holds a critical lesson in Design for Manufacturability (DFM)—the engineering practice of designing products in a way that makes them easy and efficient to manufacture. The key to effective DFM is a deep understanding of the capabilities and, more importantly, the limitations of different manufacturing processes.

For this particular component, a single, subtle design feature makes metal stamping completely unviable and positions CNC machining as the only practical solution. Let’s dive into this real-world DFM tip and explore why understanding these nuances is crucial for developing innovative, cost-effective, and successful products.

The Initial Question: Why Not Just Stamp It?

To understand the solution, we must first appreciate the problem. A project manager or designer looking at this part might reasonably ask, “Why can’t we stamp this?” Stamping is a process where a sheet of metal is pressed between a custom tool and die, cutting and forming it into a desired shape with incredible speed. For flat parts with holes, it’s a go-to method for mass production.

The perceived benefits would be:

- High Speed: Once the tool is made, parts can be produced in a matter of seconds.

- Low Per-Part Cost: At very high volumes, the cost per piece becomes extremely low.

Based on the part’s general shape, stamping seems like a perfect fit. However, a closer look at the geometry reveals the fatal flaw in this assumption.

The Critical DFM Insight: Stamping Cannot Add Material

The decisive feature on this aluminum plate is the pair of raised bosses surrounding the two oval cutouts. These bosses are taller than the base thickness of the plate itself.

This is where the fundamental physics of metal stamping become a hard limitation. Stamping is a process of cutting and forming. It can punch holes, bend flanges, and create shallow indentations or ribs (a process called coining or drawing). However, all these operations are performed on a sheet of metal with a fixed initial thickness.

Think of it like working with a sheet of pizza dough. You can cut shapes out of it, and you can stretch it to make it thinner in some areas, but you can’t create a thick crust that’s taller than your original dough ball without adding more dough.

If you were to attempt to form these tall bosses using a stamping die, one of two things would happen:

- Extreme Material Thinning: The die would try to stretch the aluminum from the surrounding area up into the boss shape. This would cause the material on the walls and top of the boss to become paper-thin, severely compromising its strength.

- Tearing and Fracture: More likely, the material would be stretched beyond its elastic limit and simply tear or crack, resulting in a failed part.

The DFM Rule: A stamped or formed metal part cannot have features that are significantly taller than the initial thickness of the sheet metal. The material simply isn’t there to create them.

The Superior Solution: The Power of Subtractive CNC Machining

This is where CNC machining provides an elegant and effective solution. Unlike stamping, which starts with a thin sheet, CNC machining is a subtractive process. It flips the entire manufacturing script.

We start not with a thin sheet, but with a solid block of aluminum.

From this solid block, a computer-controlled cutting tool precisely carves away all the excess material, leaving behind only the final, intended geometry.

This approach effortlessly solves the challenges presented by this design:

- Varying Feature Heights: Creating raised bosses that are taller than the base is trivial for a CNC machine. The machine simply removes material from the surrounding area, leaving the bosses at their full, specified height with no loss of structural integrity.

- Independent of Base Thickness: The height of the features is completely independent of the plate’s final thickness. We could make the base 1mm thick and the bosses 5mm tall, a feat impossible for stamping.

- Sharp Edges and Tight Tolerances: CNC machining excels at creating sharp, precise edges and holding dimensional and positional tolerances that are far tighter than what is practical with stamping.

- Complex Geometries: The fine grooves on the surface of the plate are another feature easily created during the CNC milling process, adding functionality (e.g., for heat dissipation or grip) that would be difficult to incorporate into a stamping die.

Beyond the Part: When to Choose CNC vs. Stamping

This case study is a perfect microcosm of a larger DFM strategy. Understanding when to use each process is key to avoiding costly mistakes and delays.

Choose Metal Stamping When:

- Volume is Extremely High: You are producing tens of thousands to millions of identical parts.

- The Design is Flat or Has Simple Bends/Forms: All features can be created from a single sheet without requiring material to be “added.”

- The Design is 100% Finalized: You are prepared to invest in expensive, permanent tooling.

- Wider Tolerances are Acceptable.

Choose CNC Machining When:

- Volume is Low-to-Mid Range: Ideal for prototypes and production runs from one to approximately 10,000 pieces where the high cost of a stamping die is not justifiable.

- The Part has Complex 3D Features: This includes raised bosses, varying wall thicknesses, deep pockets, or undercuts.

- Tight Tolerances are Critical: When precision fit and function are non-negotiable.

- Speed-to-Market is a Priority: You can go directly from a CAD file to a finished part in days, without waiting weeks for tooling.

Conclusion: DFM is a Partnership

Innovative designs often push the boundaries of what’s possible. The key to success is ensuring those designs are also manufacturable and cost-effective. This aluminum plate is a powerful reminder that the best design outcomes happen when there is a collaborative partnership between the designer and the manufacturer. By understanding the core capabilities of processes like CNC machining, engineers can design with greater freedom, confident that their vision can be brought to life without compromise.

Hope this insight helps on your next project! If you have a design and are questioning the best manufacturing path, our team of experts is here to help you navigate the options. ⚙️