In the pursuit of engineering excellence, certain materials stand apart. They offer performance characteristics so compelling that they can redefine what’s possible in a product’s design. Magnesium alloy is one of those materials.

Prized for possessing the best strength-to-weight ratio of any commonly used structural metal, it’s a designer’s dream for applications where every gram counts—from aerospace components and high-performance automotive parts to portable electronics and medical devices.

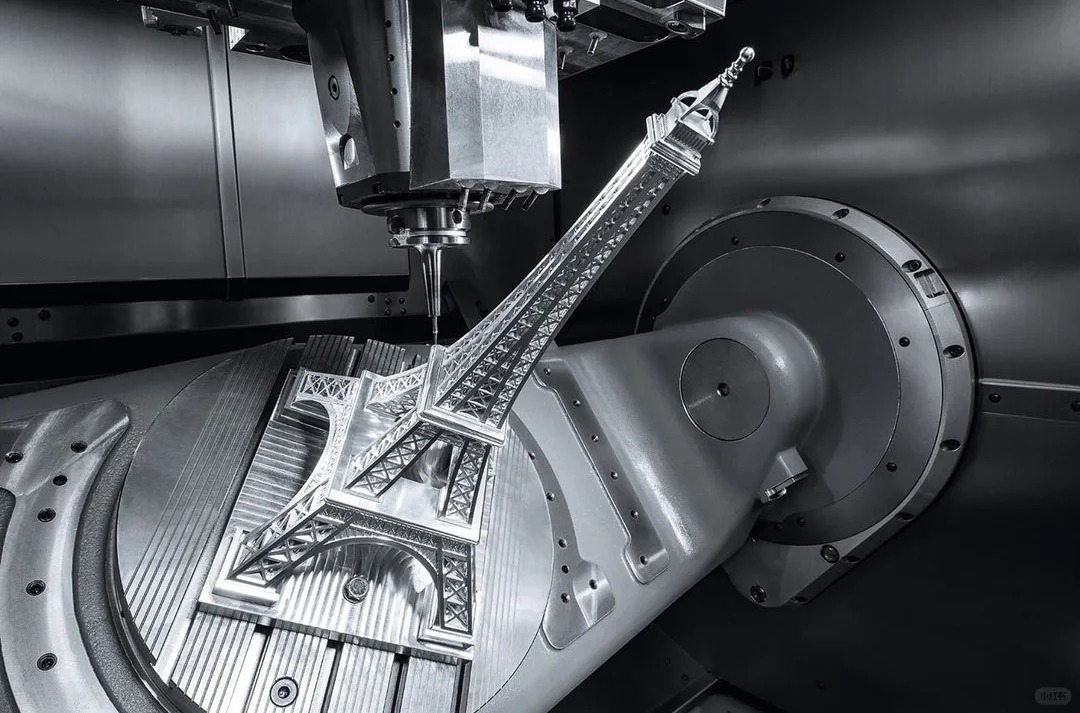

But there’s a reason many machine shops will turn down a project involving magnesium. As the video above showcases—a flawless, intricately machined component handled with the utmost care—working with this material requires more than just a CNC machine. It demands a deep level of expertise, specialized processes, and an unwavering commitment to safety. Magnesium is a material that rewards expertise and severely punishes carelessness. Its secret? It can be highly flammable during the machining process.

So, how do you bridge the gap between magnesium’s incredible potential and its manufacturing challenges? This is where a true manufacturing partner proves its worth. Let’s explore why magnesium is such a desirable material and demystify the expert-level processes required to machine it safely and precisely.

The Allure of Magnesium: Why It’s Worth the Effort

Before diving into the “how,” it’s crucial to understand the “why.” Engineers and designers specify magnesium for several key advantages that other materials simply cannot match:

- Unmatched Strength-to-Weight Ratio: This is the headline feature. Magnesium is approximately 33% lighter than aluminum and 75% lighter than steel, yet it offers comparable or superior strength to many aluminum alloys. This “lightweighting” is critical in industries like aerospace (improving fuel efficiency), motorsport (increasing speed and handling), and robotics (reducing inertial loads).

- Excellent Machinability: Ironically, when handled correctly, magnesium is one of the easiest metals to machine. It allows for higher cutting speeds and feeds than aluminum, leading to shorter cycle times and reduced manufacturing costs. This also means it can produce an exceptionally smooth surface finish directly from the machine.

- Superior Damping Capacity: Magnesium is remarkably effective at absorbing vibration and shock. This makes it an ideal choice for components in high-vibration environments, such as housings for sensitive optical equipment, audio components, and power tool casings, where it can reduce noise and improve user comfort.

- EMI/RFI Shielding: As a metal, magnesium provides excellent shielding against electromagnetic and radio-frequency interference, a crucial property for enclosures in telecommunications and consumer electronics.

With these benefits, it’s clear why magnesium is a first-choice material for cutting-edge applications. The challenge lies entirely in the manufacturing process.

Understanding the Risk: The Science of Machining Magnesium

The primary hazard associated with machining magnesium is its flammability. While a solid block of magnesium is perfectly stable, the machining process creates fine chips and dust. Under the right conditions—namely, the heat generated by the cutting tool—this fine debris can ignite in the presence of oxygen.

A magnesium fire is particularly dangerous because traditional fire-fighting methods can make it catastrophically worse. Applying water or a standard CO2 extinguisher to a magnesium fire can cause a violent reaction that releases flammable hydrogen gas, essentially adding fuel to the fire. It requires a Class D fire extinguisher, which contains a specialized dry powder agent to smother the flames.

This inherent risk is why a specialized protocol is not just recommended; it’s absolutely mandatory.

The Protocol for Precision: How We Machine Magnesium Safely

Taming magnesium requires a systematic approach that addresses heat, debris, and the overall environment. Here is our proven methodology for delivering lightweight, precision-machined magnesium parts without compromising safety or quality.

1. Specialized Cutting Fluids and Optimized Parameters

Heat is the enemy. The entire machining strategy is built around keeping the cutting zone as cool as possible.

- No Water-Based Coolants: This is the first and most important rule. Using water-based coolants would be like having a can of gasoline next to an open flame. We utilize specialized, non-water-based cutting fluids, typically oil-based, that are specifically designed for reactive metals. These oils provide excellent lubrication and cooling without the risk of a chemical reaction.

- Controlled Feeds and Speeds: While magnesium can be cut quickly, we use carefully calculated parameters to prevent excessive heat buildup. This involves maintaining a high chip load (taking a “bigger bite”) to carry heat away with the chip, rather than letting it soak into the tool or workpiece.

- Extremely Sharp Tooling: A dull tool doesn’t cut; it rubs and plows through material, generating immense friction and heat. We use dedicated, extremely sharp cutting tools, often with specific geometries and coatings optimized for magnesium, and adhere to a strict tool replacement schedule.

2. Advanced Chip and Dust Management

Controlling the byproducts of machining is the second pillar of safety. A clean machine is a safe machine.

- Aggressive Chip Evacuation: We design our processes to remove chips from the cutting zone instantly. This can involve high-pressure jets of oil-based coolant or compressed air to blast chips away as soon as they are formed, preventing any accumulation near the hot cutting tool.

- Controlling Chip Size: Our machining strategies are designed to produce coarse, thick chips rather than fine, powdery dust. Thicker chips are much harder to ignite.

- Dedicated Housekeeping: Machines used for magnesium are cleaned thoroughly and frequently to prevent any accumulation of combustible dust. All collected chips and dust are stored safely in sealed, clearly labeled metal containers, away from any potential ignition sources.

3. Deep Material Expertise and Safety Protocols

Technology and process are vital, but they are most effective when guided by human expertise and a culture of safety.

- Strategic CAM Programming: Our programmers have years of experience with magnesium’s unique properties. They create toolpaths that are not only efficient but inherently safe, minimizing tool engagement time in deep pockets and ensuring smooth, cool cutting.

- Operator Training: Every machinist who works with magnesium undergoes extensive training on its specific risks and the safety protocols required, including the proper use of Class D fire extinguishers.

- Environment Control: Our facility is equipped with the necessary safety equipment, and all magnesium work is conducted in a controlled area with strict protocols for material handling and waste disposal.

Conclusion: Turn Your Lightweighting Vision into a Reality

Magnesium offers a transformative advantage for products where weight and performance are critical. While its manufacturing presents unique challenges, these challenges are entirely manageable with the right knowledge, equipment, and safety-first mindset.

The result of this meticulous process is what you see in the video: a dimensionally perfect, lightweight component, ready to give your product a competitive edge.

Don’t let the complexities of specialty materials limit your design innovation. By partnering with a machine shop that has proven expertise in materials like magnesium, you can confidently leverage their incredible properties.

Are you developing a product that could benefit from the unparalleled strength-to-weight ratio of magnesium? Contact our engineering team today. We’re ready to discuss your project and demonstrate how our advanced manufacturing solutions can bring it to life safely and precisely.