In the world of high-performance and luxury automotive design, greatness is not defined by the broad strokes alone. The engine, the chassis, the silhouette—these are the foundations. But perfection, the kind that creates true brand loyalty and commands a premium price, lives in the final 5%. It’s in the tactile feel of a switch, the precise alignment of a body panel, and the final, parting glance a car gives as it drives away.

Nowhere is this philosophy more evident than in the exhaust tip.

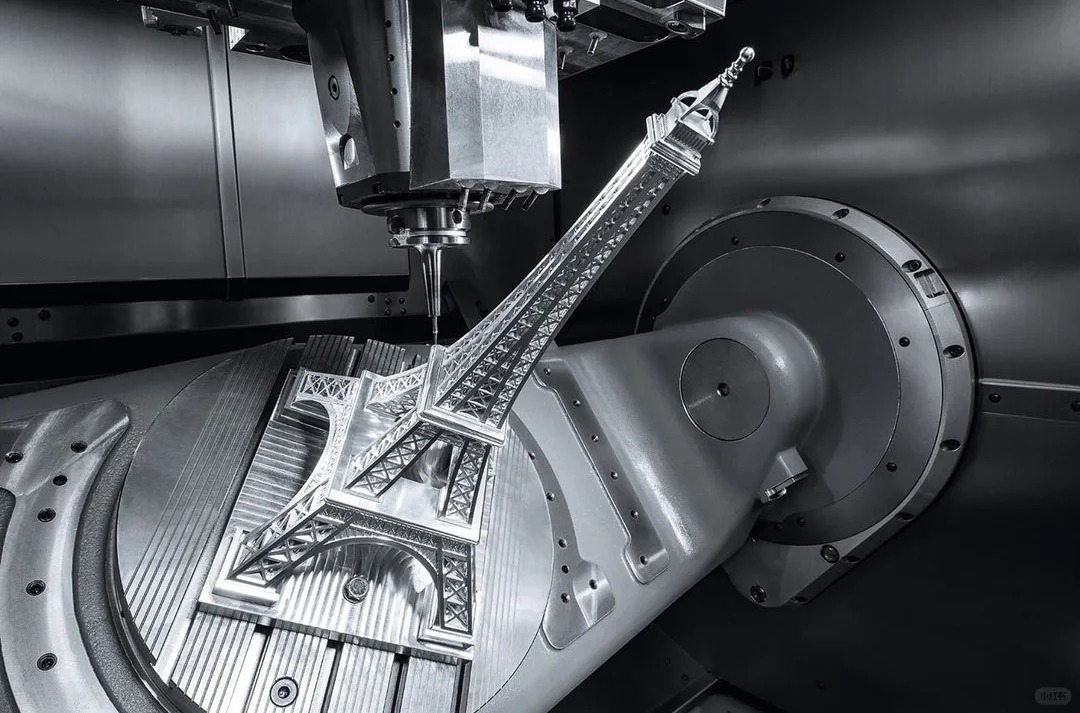

For the uninitiated, an exhaust tip is simply a functional outlet for gases. But for discerning designers, performance brands, and enthusiasts, it is so much more. It is a brand statement, a piece of industrial art, and the final, visible promise of the performance that lies within. The collection of intricately machined components in the video speaks to this ethos—where every part, no matter how small, is an exercise in precision.

An off-the-shelf, chrome-plated tube simply cannot convey the same message as a custom CNC-machined component sculpted from a solid block of stainless steel. Let’s explore what it takes to manufacture a part that is both a high-performance component and a work of industrial art, and why this final detail is anything but optional.

More Than an Exit: The Exhaust Tip as a Brand Statement

Before diving into the manufacturing complexities, it’s crucial to understand the strategic role of the exhaust tip in modern automotive design.

- Aesthetic Signature: Think of the iconic quad tips of a Corvette, the integrated hexagonal outlets of a Lamborghini, or the bold, single oval of a high-end Porsche. These are not accidents; they are deliberate design signatures that are as recognizable as the badge on the hood. They complete the visual language of the car’s rear fascia and communicate its performance pedigree.

- Perceived Quality: The final touchpoint of a vehicle leaves a lasting impression. A flimsy, poorly-fitted exhaust tip can subconsciously devalue the entire car. Conversely, a solid, perfectly integrated, beautifully finished component communicates a deep commitment to quality that extends to every part of the vehicle, seen and unseen.

- Acoustic Engineering: While the muffler and resonators do the heavy lifting, the shape, size, and material of the exhaust tip can subtly influence the final exhaust note, adding to the auditory experience of the vehicle.

For these reasons, world-class automotive brands and aftermarket tuners cannot settle for “good enough.” They require a manufacturing process that can translate their unique design vision into a flawless physical reality.

The Manufacturing Trifecta: How Perfection is Machined

Creating a component that meets these exacting standards of both performance and art requires a mastery of advanced manufacturing techniques. It is a three-part process that combines cutting-edge technology with meticulous craftsmanship.

1. 5-Axis Geometry Mastery: Sculpting from Solid

The most striking feature of a high-end exhaust tip is its geometry. It often involves seamless, organic transitions from a circular pipe to a complex oval, rectangular, or trapezoidal shape, all while perfectly contouring to the vehicle’s bumper or diffuser.

This is impossible to achieve with simple tube bending or basic fabrication. It demands the capabilities of 5-axis CNC machining.

- What is 5-Axis Machining? Unlike traditional 3-axis machines, which move a tool in X, Y, and Z, a 5-axis machine can also tilt and rotate the tool or the workpiece. This allows it to approach the part from virtually any angle in a single setup.

- The Advantage for Automotive Design: This capability is what allows us to create monolithic, seamless shapes. We start with a solid block of high-grade stainless steel (like 304 or 316 for its corrosion resistance) and carve away all non-essential material. The result is a single, solid piece with flawless transitions and complex internal and external surfaces—free of the welds, seams, or distortion marks that would be inevitable with fabrication. This not only looks better but is also structurally stronger.

2. Mirror Finish Durability: The Science of the Shine

A brilliant, mirror-like polish on an exhaust tip isn’t just for show; it’s a critical functional requirement. This is a component that lives in one of the harshest environments on a vehicle, constantly exposed to extreme heat, corrosive exhaust gases, road salt, and grime.

A standard chrome plating would quickly peel, discolor, or pit under these conditions. A true mirror polish on solid stainless steel, however, is incredibly durable.

- The Multi-Stage Process: Achieving this finish is an art form. It begins with a superior surface finish directly from the CNC machine, using optimized toolpaths and sharp tooling. From there, it moves to a multi-stage manual or robotic polishing process, using progressively finer abrasive compounds to remove any microscopic machining marks until the surface is perfectly smooth and reflective.

- Functional Benefits: A highly polished, non-porous surface is more than just beautiful. It is more resistant to corrosion and makes it much harder for carbon buildup and dirt to adhere, ensuring the component stays flawless for years with minimal maintenance.

3. Factory-Perfect Fitment: The OEM-Level Standard

For both OEM applications and the high-end aftermarket, the final fit is non-negotiable. The gaps between the exhaust tip and the bumper cutout must be perfectly even and consistent. The alignment must be exact. This is what screams “factory quality” versus a cheap add-on.

- Precision is Paramount: This is achieved through a commitment to quality control at every stage. Using a Coordinate Measuring Machine (CMM), we can inspect the finished parts and verify their dimensions against the original CAD model to within a few microns.

- Guaranteed Consistency: This digital-first approach ensures that whether we are making a one-off prototype or a low-volume production run of 500 units, every single part will fit as perfectly as the last. This reliability is crucial for performance brands that need to guarantee a flawless installation experience for their customers.

Performance or Aesthetics? The Answer is “Yes.”

Would you prioritize performance or aesthetics in your next automotive component? For a premium product, this is a false choice. The two are inextricably linked. A component that performs brilliantly but looks poorly made undermines the user’s confidence in its engineering. A beautiful component that fails to perform is an empty promise.

The ultimate goal, and what we specialize in, is creating components where exceptional performance and stunning aesthetics are one and the same. A smoothly machined internal flow path for better exhaust velocity also happens to be a hallmark of quality craftsmanship. A durable, heat-resistant mirror finish is both a visual delight and a functional necessity.

For automotive designers and performance brands, this level of detail is the final handshake with your customer—the promise of excellence, realized in metal.

Planning an automotive component where every detail matters? Let’s collaborate to turn your design vision into a flawless, high-performance reality. 🤝