1. Defining Quality in CNC Machined Parts

Quality in CNC machining encompasses several critical aspects:

- Dimensional Accuracy & Tight Tolerances: This is perhaps the most recognized benefit. It refers to how closely the machined part conforms to the dimensions specified in the CAD model. Tolerances define the permissible range of variation. High-quality machining achieves very tight tolerances, often measured in microns (µm).

- Surface Finish: The texture and smoothness of the machined surfaces. A good surface finish can be critical for aesthetics, sealing, friction reduction, or subsequent processes like painting or plating. Surface roughness (Ra) is a common metric.

- Geometric Dimensioning and Tolerancing (GD&T): Beyond simple dimensions, GD&T defines the allowable variation in a part’s form, orientation, profile, and location of features relative to each other. Adherence to GD&T callouts is vital for complex assemblies.

- Material Integrity: Ensuring the chosen plastic or metal material is not compromised during the machining process (e.g., no excessive heat buildup causing warping, no contamination).

- Consistency and Repeatability: Producing identical parts within specified tolerances across an entire production run, whether it’s for a few prototypes or hundreds of components.

- Absence of Defects: Freedom from burrs, tool marks, chatter, cracks, or other imperfections that could affect performance or appearance.

2. Factors Influencing CNC Machining Quality

Achieving top-tier quality is a result of careful control over multiple factors:

- Machine Tool Capability & Calibration:

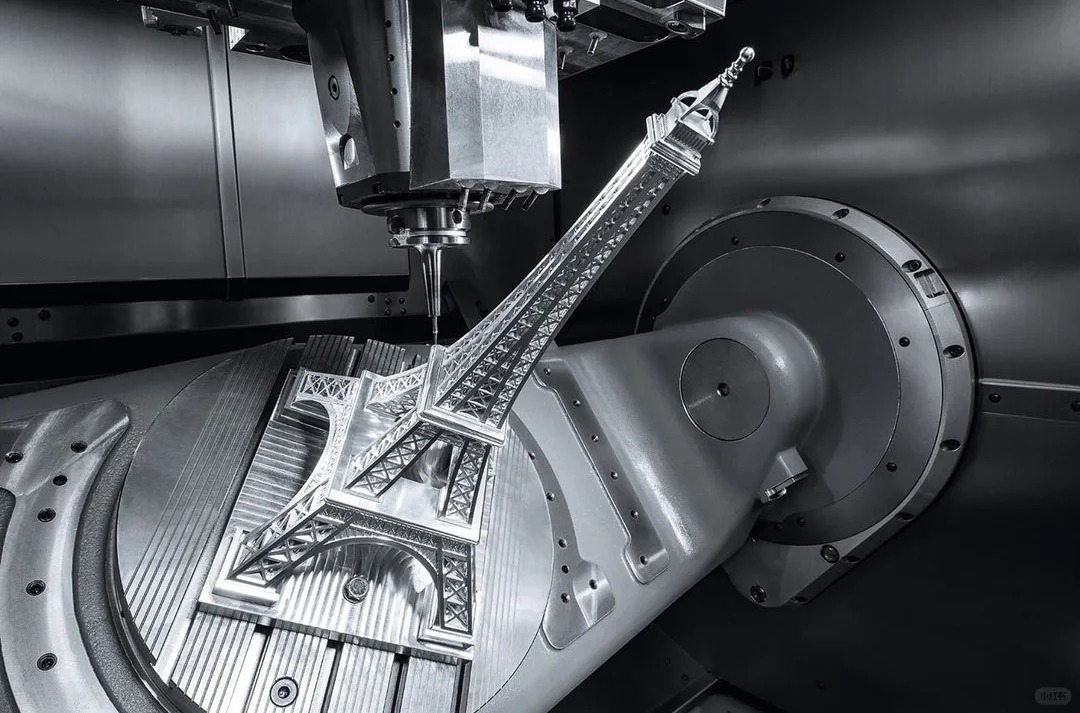

- High-Quality Machines: State-of-the-art CNC machines (mills, lathes, 5-axis centers) with robust construction, high spindle speeds, and precise motion control systems are foundational.

- Regular Maintenance & Calibration: Ensures machines perform accurately over time, compensating for any wear or drift.

- Cutting Tools:

- Tool Selection: Using the right type of cutting tool (end mills, drills, reamers, etc.), made from appropriate materials (e.g., carbide, HSS), and with the correct geometry for the specific plastic or metal being machined and the desired feature.

- Tool Condition: Sharp, well-maintained tools are crucial. Worn or chipped tools lead to poor surface finish and dimensional inaccuracies.

- Workholding & Fixturing: Securely and accurately holding the workpiece is paramount. Poor fixturing can lead to vibrations, tool deflection, and inaccurate parts. Custom fixtures may be needed for complex geometries.

- CAM Programming Expertise:

- Optimal Toolpaths: Skilled CAM programmers create efficient and precise toolpaths that minimize tool wear, reduce machining time, and achieve the desired surface finish and accuracy.

- Speeds and Feeds: Selecting the correct cutting speeds (how fast the tool rotates) and feed rates (how fast the tool moves through the material) is critical for material removal and finish.

- Operator Skill & Experience: While CNC is automated, skilled operators are essential for setup, monitoring the process, making adjustments, and performing initial quality checks.

- Material Quality & Preparation: Starting with high-quality, consistent raw material is important. Proper material preparation might also be necessary.

- Quality Control & Inspection Processes:

- In-Process Inspection: Checking parts at various stages of machining.

- Final Inspection: Using precision measuring tools (calipers, micrometers, CMMs – Coordinate Measuring Machines, optical comparators) to verify all dimensions, tolerances, and GD&T requirements.

- Documentation: Maintaining records of inspections and quality checks.

3. How Paulinetech Prioritizes Quality in CNC Machining

At Paulinetech, quality is ingrained in every step of our CNC machining process, from initial consultation for your plastic product industrial design to the delivery of finished parts:

- Investment in Technology: We utilize modern, well-maintained CNC equipment capable of achieving tight tolerances and excellent surface finishes.

- Skilled Team: Our engineers, CAM programmers, and machine operators are experienced professionals dedicated to precision.

- Rigorous Processes: We follow established procedures for programming, setup, machining, and inspection.

- Material Expertise: We understand the unique machining characteristics of various engineering plastics and select appropriate tooling and parameters accordingly.

- Comprehensive Quality Assurance: We employ a multi-stage inspection process, including the use of advanced metrology equipment, to ensure every part meets your exact specifications.

- Collaboration with Design: For clients using our industrial design services, we ensure Design for Manufacturability (DFM) principles are applied early on, optimizing for quality and efficiency in the CNC process.

4. The Value of High-Quality CNC Machined Parts

Investing in quality CNC machining offers significant returns:

- Reliable Performance: Parts that fit and function as intended, reducing assembly issues and field failures.

- Product Longevity: Well-made components contribute to the overall durability and lifespan of your plastic product.

- Reduced Waste & Rework: Getting it right the first time saves time and money.

- Brand Reputation: High-quality components reflect positively on your brand and product.

- Successful Prototyping: Accurate prototypes provide reliable data for design validation, leading to better final products.

Conclusion: Demand Precision, Expect Excellence

When it comes to CNC machining for your custom plastic parts or industrial design prototypes, settling for anything less than the highest quality can compromise your entire project. By understanding the factors that contribute to precision and partnering with a provider committed to excellence, you can be confident in receiving components that meet your most demanding requirements.