In the world of advanced engineering, a product is rarely defined by a single, heroic component. Instead, its true power, performance, and reliability are born from a symphony of precision parts working in perfect, seamless harmony. This isn’t just a collection of individual components—it’s an integrated system where every piece, no matter how large or small, plays a vital and interconnected role.

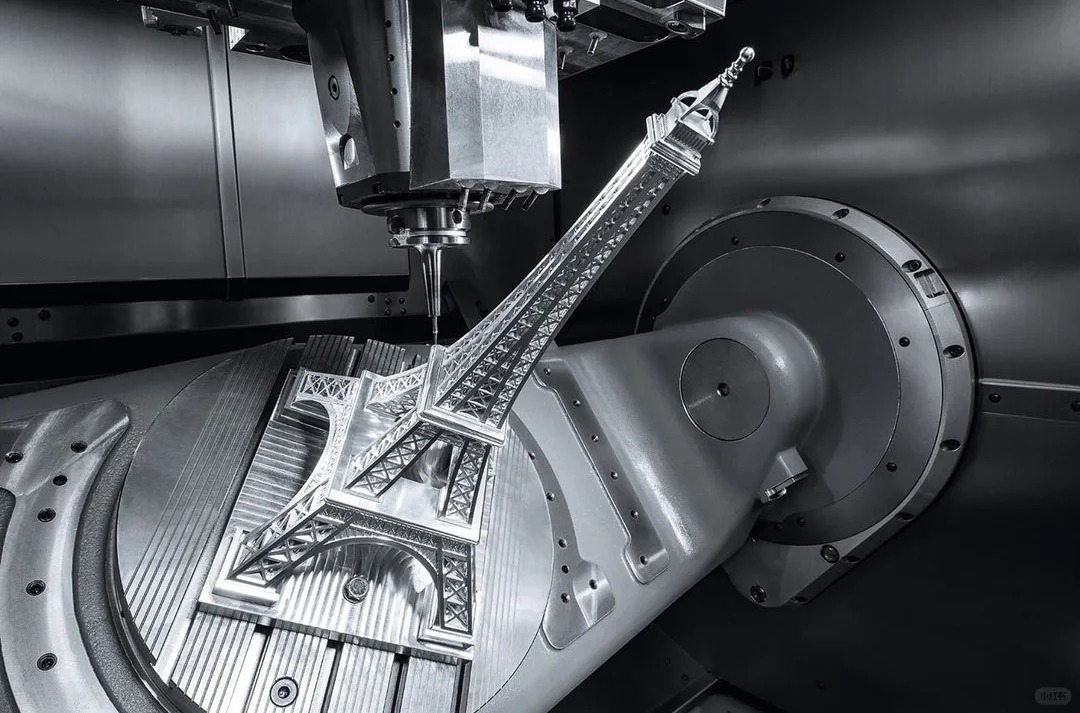

The array of custom CNC-machined parts showcased in the video is a powerful illustration of this principle. At first glance, it’s an impressive display of manufacturing capability. But look closer, and you see the story of a complete electromechanical or fluidic system, where a structural backbone, a thermal management solution, a liquid cooling block, and micro-mechanisms must all come together flawlessly to create something truly functional and powerful.

This is the essence of modern product development. True engineering excellence isn’t just about making one perfect part; it’s about mastering the complexity of the entire assembly. This requires a manufacturing partner with not only a diverse range of technical capabilities but also a holistic, system-level understanding of how these pieces must integrate.

Let’s take a deep dive into the individual roles of these components and explore the unique manufacturing challenges each presents, revealing how system-level precision is achieved.

1. The Structural Core: The Foundation of Alignment and Integrity

At the heart of any complex assembly is a structural core or chassis. In this set, it’s the large, intricate component with multiple mounting points, cutouts, and precisely located bores. This is the backbone that holds everything else in perfect alignment.

- The Function: This part serves as the master datum for the entire system. Its geometric accuracy dictates whether the optics will align, the gears will mesh, or the fluid connectors will seal. The slightest deviation here can cause a catastrophic failure in the final assembly.

- The Manufacturing Challenge: The geometry is inherently complex, with features on all six sides, including angled holes and deep pockets. Creating such a part with traditional 3-axis machining would require multiple setups, increasing the risk of tolerance stack-up and positional errors with each new clamping.

- The Solution: 5-Axis Machining Mastery: This is a textbook application for 5-axis CNC machining. By allowing the cutting tool to approach the workpiece from any angle in a single setup, we can machine all critical features in one continuous operation. This preserves the perfect geometric relationship between every bore, face, and mounting point, ensuring the foundation of your assembly is dimensionally perfect and structurally uncompromised.

2. The Heatsink: Engineering for Optimal Thermal Performance

High-performance systems generate heat, and managing that heat is critical for reliability and longevity. The custom heatsink, with its array of ultra-fine fins, is the system’s primary thermal management solution.

- The Function: Its sole purpose is to draw heat away from sensitive electronics and dissipate it into the surrounding air. The more surface area it has, the more effectively it can do this.

- The Manufacturing Challenge: Machining ultra-thin, deep fins is a delicate process. The high-frequency vibrations from the cutting tool can cause the thin walls to “ring” or deform, compromising the finish and dimensional accuracy. Furthermore, chip evacuation from deep, narrow channels is a significant challenge.

- The Solution: Advanced Machining Strategies: This requires more than just a capable machine; it requires expert programming. We use specialized cutting tools, optimized toolpaths (like high-speed trochoidal milling), and precisely controlled feeds and speeds to cut these delicate features without inducing vibration. This allows us to create fins that are thinner and more densely packed than what’s possible with extrusion, maximizing surface area and cooling performance within a compact footprint.

3. The Fluid Block: Mastering Complex Internal Channels

For even more demanding thermal loads, active liquid cooling is necessary. The small block with serpentine internal channels is a custom-designed cold plate or fluid manifold.

- The Function: A coolant (like water or glycol) flows through these internal channels, absorbing heat directly from a high-power component and carrying it away to a radiator.

- The Manufacturing Challenge: The integrity of these internal channels is paramount. Any surface imperfections can disrupt fluid flow and reduce efficiency. Any burrs left from machining can dislodge and clog the system. Most importantly, the part must be absolutely leak-proof, often under high pressure.

- The Solution: Precision Milling and Flawless Finishing: Creating these channels requires precise 3D milling. After machining, the component undergoes a meticulous deburring and finishing process to ensure the internal pathways are perfectly smooth. Often, these blocks are machined in two halves with a groove for an O-ring, then sealed together, requiring the mating surfaces to be perfectly flat to guarantee a high-pressure, leak-proof seal.

4. The Micro-Mechanisms: Precision at the Smallest Scale

A complex system is often defined by its smallest components. The tiny nozzles, connectors, and brackets are the critical interfaces that make everything work.

- The Function: These parts could be anything from a fluid nozzle to a fiber optic connector to a specialized alignment pin. Their function relies on micro-scale precision.

- The Manufacturing Challenge: Working at this scale presents unique challenges. Tolerances are often measured in single microns. Features like tiny orifices, fine threads, and delicate retention clips require specialized tooling and machinery, such as Swiss-style CNC lathes or micro-milling centers.

- The Solution: Micro-Machining Expertise: This is a specialized discipline that combines the right equipment with a deep understanding of how materials behave at a small scale. Holding and machining these tiny parts without deforming them requires custom fixturing and an expert touch, ensuring that even the most diminutive component performs its critical function reliably.

The Power of the Assembly: Why a Holistic Partner Matters

As we’ve seen, each component presents a unique set of manufacturing challenges. A great heatsink requires different skills than a great structural frame. This is why a holistic, single-source manufacturing partner is so invaluable.

A true partner understands that they aren’t just making individual parts to a print. They are manufacturing a system. They bring an “assembly-level” DFM (Design for Manufacturability) perspective to the table, analyzing how tolerances will stack up, how different surface finishes will interact, and how the entire ecosystem of parts will come together.

This approach de-risks your project, streamlines your supply chain, and ensures that the precision engineered into every individual piece translates into powerful, reliable performance in the final assembly.

When you are designing your next complex assembly, what is your single biggest manufacturing consideration? Is it tolerance control, material selection, thermal management, or something else entirely? Share your thoughts below. 👇